2026 Top Features of Tablet Coating Pan for Optimal Production Efficiency?

In the pharmaceutical and confectionery industries, the tablet coating pan is integral to production efficiency. According to a recent report by Grand View Research, the global tablet coating market is expected to reach $3.2 billion by 2027, driven by increasing demand for coated tablets. This highlights the importance of optimizing coating processes for better output.

The tablet coating pan has evolved significantly. Enhanced designs now support greater control over parameters like temperature and humidity. A study by PharmTech reveals that improving these parameters can reduce production time by up to 30%. However, many manufacturers overlook the importance of regular maintenance, which can lead to inconsistent quality and delayed production.

Achieving optimal production efficiency requires attention to various features of tablet coating pans. Factors such as coating uniformity, batch consistency, and equipment reliability are vital. Some facilities still use outdated machinery, causing inefficiencies in the process. As the industry progresses, reflection on these shortcomings is necessary to stay competitive.

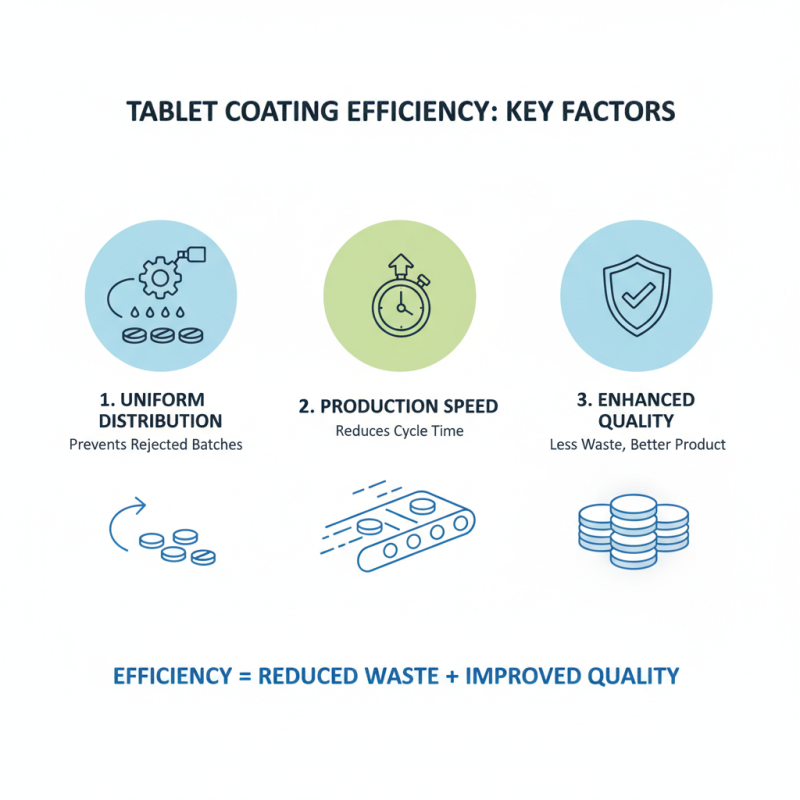

Key Factors Influencing Tablet Coating Efficiency in Production

When it comes to tablet coating, efficiency is key. Several factors significantly influence production efficiency. One vital aspect is the uniform distribution of coating material. Inconsistent application can lead to rejected batches. Operators need to ensure even coating across all tablets. This reduces waste and enhances quality.

Humidity levels play a critical role as well. High humidity can affect the drying process. Tablets may become sticky and clump together. This delays production and can require additional cleaning steps. Monitoring environmental conditions can help prevent these issues. Effective airflow can also promote faster drying.

Tips: Always calibrate equipment before starting a batch. Regular checks can spot irregularities early. Consider testing different coating techniques to find the best fit for your product. Every setup may require adjustments. This can be a challenge, but continuous improvement is essential for optimal production.

Essential Features of Modern Tablet Coating Pans for Optimal Results

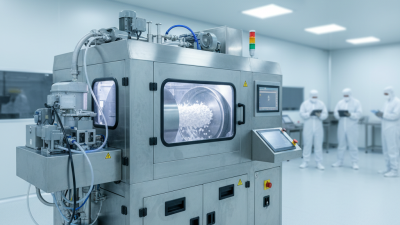

In the fast-evolving pharmaceutical industry, the design of tablet coating pans plays a crucial role in production efficiency. Modern coating pans must deliver uniform coating with minimal waste. According to industry reports, advancements in pan design can reduce coating time by up to 30%. This efficiency not only boosts productivity but also affects overall product quality.

Key features to consider in tablet coating pans include precise temperature control and adjustable airflow. These functionalities help maintain consistent coating thickness, which is vital for stability. A study highlighted that inconsistent coating can lead to a 15% increase in rejected batches. Such statistics emphasize the need for attentive design in coating machinery.

Automation and user-friendly interfaces are also critical. As manufacturers face increasing pressure for efficiency, automated systems can prevent human error. However, operators must be trained effectively to manage these systems. A survey noted that inadequate training led to a 20% increase in operational failures. This reveals a gap that could hinder optimal production efficiency in tablet coating processes.

2026 Top Features of Tablet Coating Pan for Optimal Production Efficiency

| Feature | Description | Importance |

|---|---|---|

| Uniform Coating Technology | Ensures even distribution of coating material across tablets, mitigating the risk of uneven coating. | Critical for product quality and consistency. |

| Integrated Drying System | Combines coating and drying processes in a single unit, increasing throughput. | Enhances production efficiency by reducing processing time. |

| Automatic Control Systems | Utilizes sensors and software to monitor and adjust parameters in real-time. | Ensures optimal performance and minimizes the chance for human error. |

| User-Friendly Interface | Simplified controls for easier operation and maintenance by staff. | Improves user experience and reduces training time. |

| Energy Efficiency | Reduces energy consumption during operations, leading to lower production costs. | Vital for cost management and sustainability initiatives. |

| Versatile Coating Options | Allows for application of various types of coatings (e.g., sugar, film) on different tablet forms. | Enhances product offerings and flexibility in production. |

| Clean-in-Place (CIP) Systems | Automatic cleaning systems that reduce downtime and manual labor. | Important for maintaining cleanliness and compliance with regulatory standards. |

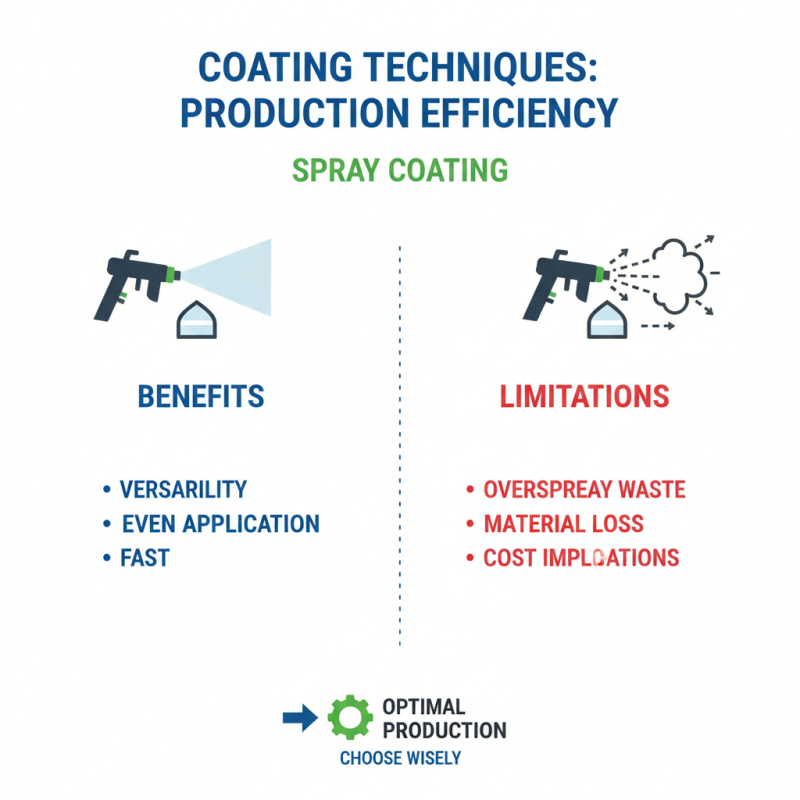

Comparison of Coating Techniques: Selecting the Best for Production Needs

In the quest for optimal production efficiency, selecting the right coating technique is crucial. Different methods offer unique benefits and limitations. For instance, spray coating is widely used for its versatility. It allows for even application but may lead to overspray, resulting in material waste. This can affect the overall efficiency of production lines.

On the other hand, fluidized bed coating provides excellent uniformity. The uniform coating results in a consistent product quality. However, this method can be slower, which might not suit every production schedule. Additionally, some operators find it challenging to control the coating thickness. These factors require careful consideration in choosing the right technique.

Another technique gaining attention is rotary pan coating. It brings high throughput and efficiency. Yet, it might struggle with highly viscous materials. Such limitations can lead to inefficiencies in specific applications. Manufacturers must analyze their production needs thoroughly. Each method has its advantages, but careful evaluation is necessary to avoid pitfalls. This reflective approach will ensure more informed decision-making.

Innovative Technologies Enhancing Tablet Coating Pan Performance

The tablet coating pan is evolving rapidly with innovative technologies. These advancements aim to enhance efficiency and product quality. One key feature is the improved heating system. It ensures uniform temperature distribution. This helps achieve consistent coating results.

Another significant technology is the integration of automation. Automated systems reduce manual intervention. They increase precision and decrease production time. Operators can program specific parameters for various products. This flexibility adapts to changing production needs.

**Tips:** Monitor the temperature closely. Inconsistent heat may lead to uneven coatings. Regularly inspect the coating pan for wear and tear. Maintenance is crucial for prolonged performance. Stay updated with new technologies that could improve operations further.

Best Practices for Maintenance and Operation of Coating Equipment

Maintaining coating equipment requires a strategic approach. Regular cleaning is vital. A study shows that neglecting routine maintenance can lead to a 20% drop in production efficiency. Operators should inspect for wear and tear monthly. Replacing worn parts promptly helps maintain optimal functionality.

Temperature control is essential in tablet coating processes. The ideal range is typically between 50°C and 70°C. Deviating from this range can result in uneven coating. Operators must monitor equipment temperature closely. Inconsistent temperatures can compromise product quality and increase rework rates, leading to inefficiencies.

Training staff on best practices is crucial. Knowledge gaps can lead to operational errors. A report from the Coating Technology Association indicates that well-trained operators can enhance efficiency by 15%. Regular workshops and refresher courses can bridge these gaps. Mistakes happen, but learning from them is key to improvement.

Related Posts

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality

-

The Best Pharmaceutical Coating Techniques for 2026

-

Top 10 Tips for Choosing the Right Pharma Coating Machine for Your Needs

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

How to Choose the Best Film Coating for Your Projects and Applications