2026 Top Coating Pan Tablet Trends You Should Know?

In the rapidly evolving world of pharmaceutical manufacturing, the "coating pan tablet" industry is experiencing dynamic changes. Dr. Emily Zhang, a leading expert in tablet development, said, "The next big shift in coating technology is around the corner." As we approach 2026, understanding the emerging trends in this sector becomes crucial.

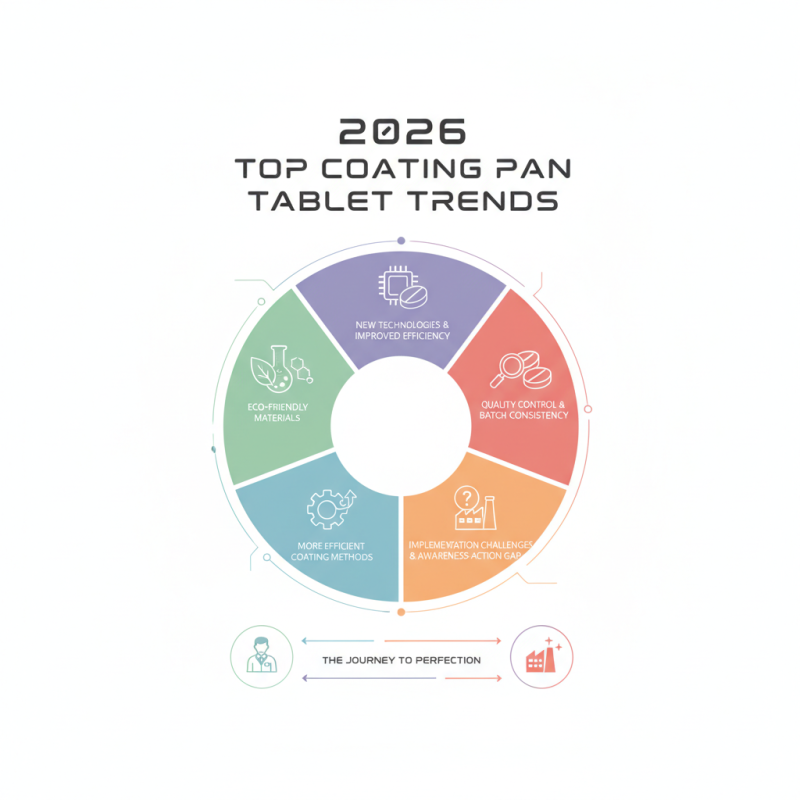

The current landscape shows innovation at its core. The rise of eco-friendly materials is on the horizon. Increasing demand for more efficient coating methods is evident. Manufacturers must adapt quickly to stay relevant. With new technologies, the efficiency of coating pan tablet production can improve significantly. However, there is a challenge. Many companies struggle to implement these advancements. A gap between awareness and action is apparent.

Quality control remains a major concern. Many firms face difficulties in maintaining batch-to-batch consistency. The journey toward perfection in coating processes is not easy. Despite great advancements, there is still room for improvement. As we explore coating pan tablet trends for 2026, the industry must reflect on these challenges and strive for better solutions.

Emerging Technologies in Coating Pan Tablet Production

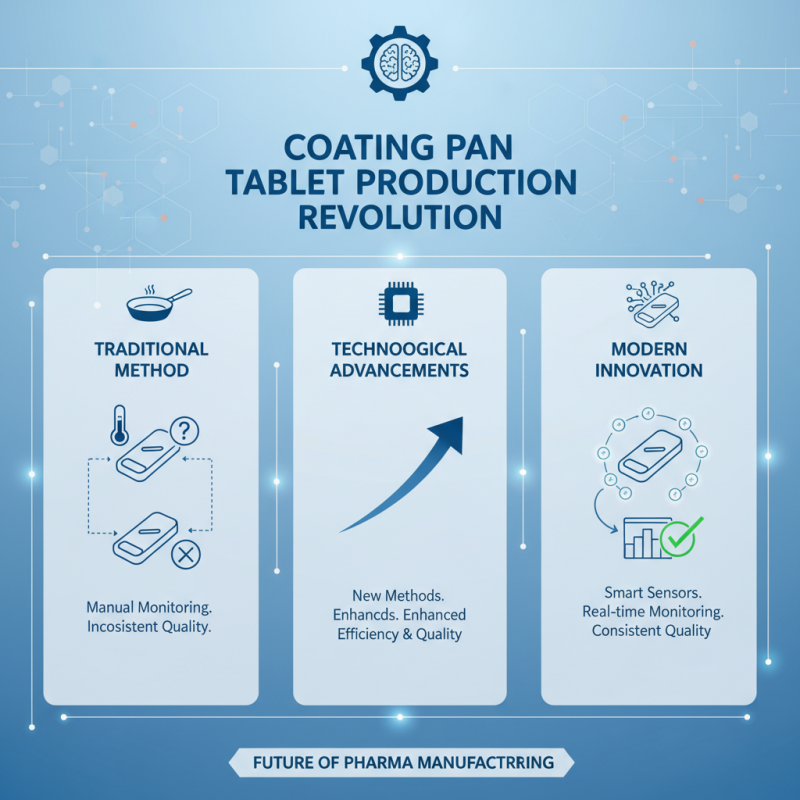

The production of coating pan tablets is experiencing a technological revolution. New methods are being developed to enhance efficiency and quality. For instance, the integration of smart sensors allows manufacturers to monitor the coating process in real time. This innovation helps in maintaining consistent quality throughout production runs.

Additionally, automation is changing how tablets are coated. Automated systems can now handle adjustments automatically, reducing the chances of human error. While this brings speed, it also raises questions. Are we sacrificing the artisanal touch? The balance between speed and quality remains a topic for discussion.

Another trend is the use of eco-friendly materials in the coating process. Manufacturers are exploring biopolymers and natural coatings. These alternatives can reduce environmental impact but may require further research. Finding the right balance between sustainability and performance is still a challenge. As the industry evolves, these emerging technologies will shape the future of coating pan tablet production.

Key Materials for Enhanced Coating Efficiency in 2026

In 2026, the coating pan tablet sector is evolving. Key materials play a critical role in enhancing coating efficiency. High-quality polymers and natural substances are in the spotlight. These materials not only improve adhesion but also enhance the tablet's appearance.

The use of biodegradable coatings is gaining traction. This aligns with eco-friendly trends. Tablets with such coatings can attract health-conscious consumers. Attention to detail in formulation can lead to better results.

Tip: Experiment with different materials to find the best combination for your specific needs.

Some industry players may overlook the importance of timing in the coating process. Coating too early or too late can lead to uneven layers. Maintaining optimal conditions is crucial.

Tip: Always monitor humidity and temperature closely.

Ultimately, the focus should be on innovation. Embrace new technologies, but don’t forget the basics. A balance of creativity and time-tested methods may yield the best products in the market.

Market Trends: Consumer Preferences Driving Coating Innovations

The coating pan tablet market is evolving rapidly. Consumer preferences are shaping innovations. According to a recent report, 68% of consumers prioritize taste and texture over traditional coating options. This trend emphasizes the need for new solutions that meet these demands.

Recent data highlights a rise in interest for natural and organic coatings. Approximately 52% of consumers seek products with fewer synthetic ingredients. This shift challenges manufacturers to innovate. They must create appealing coatings without compromising on health standards. In this competitive market, sustainability is becoming a key factor.

Tips: Focus on transparency. Share ingredient sourcing with your audience. Consider offering product samples to gather direct feedback. Addressing health-conscious consumers is crucial for market growth. It may seem daunting, but adapting to these trends can unlock new opportunities. By embracing change, businesses can enhance their appeal and meet evolving consumer expectations.

2026 Top Coating Pan Tablet Trends You Should Know

| Trend | Description | Consumer Preference (%) | Impact on Market |

|---|---|---|---|

| Organic Coatings | Increasing demand for eco-friendly, organic materials. | 45% | Positive |

| Customization | Growing interest in personalized coating solutions. | 30% | High |

| Improved Durability | Focus on enhancing the longevity of coatings. | 65% | Critical |

| Rapid Curing Technologies | Innovations that speed up the curing process. | 40% | Moderate |

| Smart Coatings | Integration of technology for enhanced functionality. | 25% | Emerging |

Sustainability Practices in Coating Pan Tablet Manufacturing

Sustainability is transforming the coating pan tablet manufacturing industry. More companies are focusing on eco-friendly practices. This shift is driven by the need for efficiency and environmental responsibility.

Reducing waste is critical. Manufacturers can optimize production processes to minimize resource use. This not only cuts costs but also lessens their carbon footprint. Using biodegradable materials is another step forward. It’s essential to rethink traditional materials and explore greener alternatives.

Tips for manufacturers: Invest in energy-efficient machinery. Consider using renewable energy sources like solar or wind. Collaborate with suppliers committed to sustainability. Providing staff with training on green practices is vital. These approaches require effort and introspection but can lead to significant improvements in sustainability. Almost every company can do better.

Competitive Analysis: Leading Companies in Coating Pan Technologies

The coating pan market is evolving rapidly. In 2026, key trends will redefine how these technologies are utilized. Competitive analysis indicates that several companies lead this space, pushing innovations and efficiency. Reports suggest that the market is projected to grow significantly, with a CAGR of over 5% from 2021 to 2026. This growth is fueled by increasing demand in pharmaceuticals and food applications.

Industry leaders are focusing on automation and sustainability. Newer coating pans are equipped with smart technology, allowing for better control and monitoring. This leads to reduced product loss and improved consistency. However, challenges remain. Some manufacturers struggle with integrating these advanced technologies into existing operations. A comprehensive strategy is needed to bridge this gap.

Tips: Regularly assess your coating process. Keep an eye on emerging technologies. Invest in training for staff to adapt to changes in equipment. Small adjustments can yield significant improvements over time. Stay updated on regulatory changes that may impact efficiency. Remember, innovation should remain user-friendly.

Related Posts

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

Why Coating Pan Tablets are Essential for Efficient Tablet Production

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process

-

How to Choose the Best Pharmaceutical Coating Machine for Your Needs