What Are the Benefits of Using a Continuous Coater in Manufacturing?

In modern manufacturing, efficiency is crucial. The use of a continuous coater offers significant advantages. This machine streamlines processes, reducing production time and labor costs. With its ability to coat a variety of substrates, it enhances flexibility in operations.

A continuous coater can provide uniform coverage, resulting in consistent product quality. It allows manufacturers to apply coatings seamlessly, reducing wastage. However, it is easy to overlook the need for regular maintenance. Neglecting this can diminish the coater’s effectiveness over time.

Investing in a continuous coater may seem expensive upfront. Yet, the long-term savings often outweigh initial costs. Manufacturers must weigh these factors carefully. While the benefits are clear, the decision requires thoughtful consideration of specific operational needs.

Overview of Continuous Coating Technology in Manufacturing

Continuous coating technology is revolutionizing the manufacturing landscape. This process allows for uniform application of coatings, ensuring consistent quality. According to a recent industry report, companies using continuous coaters have reported a 25% reduction in material waste. This efficiency not only lowers costs but also enhances sustainability efforts.

In practice, continuous coaters streamline operations by integrating multiple manufacturing steps. They can coat, dry, and cure materials in a single line. This integration is vital as manufacturers face increasing pressure to reduce cycle times. A comparative study revealed that continuous coating systems can outperform batch coating methods by up to 50% in production speed. Yet, there are challenges. Operators must consistently monitor settings to avoid defects and ensure proper adhesion.

Moreover, the technology isn't without limitations. Initial setup costs can be significant, which may deter smaller manufacturers. Adjusting to new processes also requires training and skill development. Despite these concerns, the trend toward continuous coating is growing, driven by the need for efficiency and quality in an ever-competitive market.

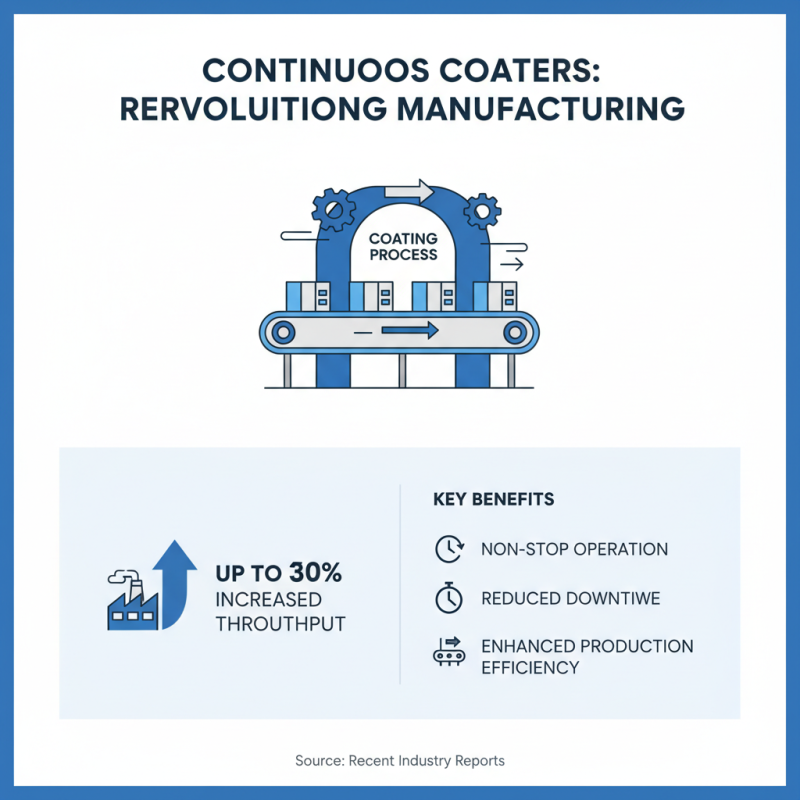

Key Benefits of Continuous Coaters in Production Efficiency

Continuous coaters are revolutionizing the manufacturing landscape. Their ability to enhance production efficiency is a game changer. According to recent industry reports, companies employing continuous coaters can achieve up to a 30% increase in throughput. This improvement reflects the coaters' capability to operate non-stop, reducing downtime during production.

For manufacturers, reducing waste is critical. Continuous coaters ensure consistent coating thickness and uniformity. This leads to less material wastage. A study indicated that uniform application can cut material costs by around 10-15%. Efficient use of materials not only reduces expenses but also supports sustainability efforts.

Tip: Regular maintenance of your coater can prevent unexpected issues. A well-maintained machine runs smoother and more efficiently.

Moreover, continuous coaters are adaptable. They can handle various substrates, from metals to plastics. This versatility helps meet diverse product demands. However, it is vital to assess the suitability of the equipment for specific product requirements. The upfront costs can be high, but the long-term savings often justify the investment.

Tip: Consider integrating new technologies to monitor and optimize the coating process. Smart technologies can provide critical insights, boosting overall efficiency.

Impact on Product Quality and Consistency with Continuous Coating

Continuous coating technology significantly enhances product quality and consistency in manufacturing. For instance, it offers a uniform application of materials across various substrates. Reports indicate that a well-executed continuous coating process can reduce thickness variation to as low as 5%. This precision directly contributes to better product performance and durability.

Moreover, continuous coaters minimize defects like bubbles or streaks that can occur in batch processes. In fact, some studies suggest that companies employing continuous coating see a defect rate drop by 20%-30%. This improvement is crucial for industries where quality is paramount, such as aerospace and automotive sectors. However, achieving perfect consistency remains challenging. Operators must frequently monitor conditions and adjust settings, which can lead to variability in results.

While the technology provides many benefits, it is not without its challenges. Initial setup costs and maintenance can be significant. Periodic calibration is essential for optimal performance but can be overlooked, leading to inconsistencies. Continuous coating requires skilled personnel who can quickly identify issues and implement solutions. Balancing efficiency with quality control remains a complex endeavor for many manufacturers.

Benefits of Using a Continuous Coater in Manufacturing

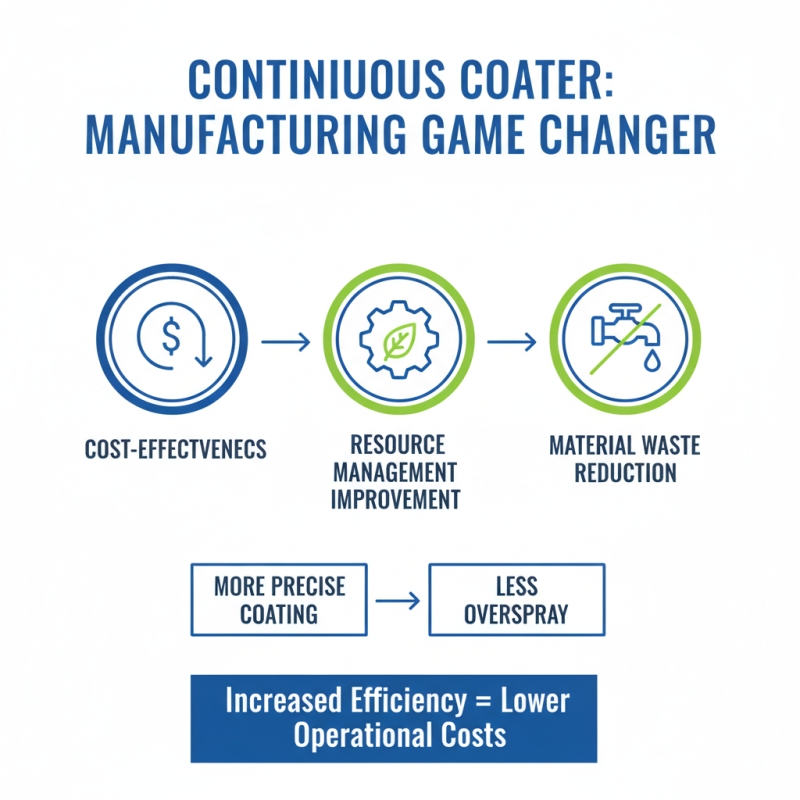

Cost-Effectiveness and Resource Management in Continuous Coating

The continuous coater is a game changer in manufacturing. It enhances cost-effectiveness and improves resource management. With this technology, companies can reduce material waste significantly. This happens because the coating process is more precise. Less overspray means fewer resources are wasted. The efficiency can lead to lower operational costs in the long run.

However, the initial investment in continuous coating equipment can be daunting for some businesses. While the long-term benefits are clear, the upfront expense may cause hesitation. Companies need to weigh the cost against potential savings. Moreover, training staff to operate such advanced machinery requires time and resources. There might be a learning curve, which can disrupt production initially.

Despite these challenges, the rewards can be substantial. A successful implementation can improve product quality, leading to higher customer satisfaction. Improved resource management also means sustainable practices, which are increasingly important today. As industries evolve, embracing continuous coaters could be a promising step, despite its complexities.

Applications of Continuous Coaters Across Different Industries

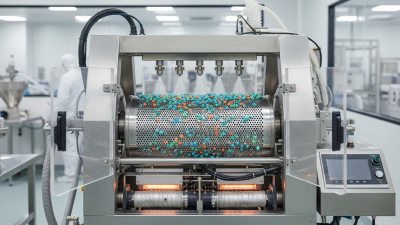

Continuous coaters serve diverse industries, providing unique advantages. In food production, these machines apply coatings evenly on snacks. The result is a consistent flavor and texture. For pharmaceutical companies, continuous coaters ensure pills have a uniform coating. This enhances drug delivery and patient compliance.

In the automotive sector, manufacturers use continuous coating for protective layers on parts. This process improves durability and reduces wear. However, there are challenges. Variability in materials can affect coating quality. Operators must constantly monitor and calibrate equipment to minimize errors.

In the electronics industry, continuous coaters deposit materials onto circuit boards. This allows for precise and efficient production. While the technology is efficient, it can lead to waste if not properly managed. Over-coating can result in additional costs and environmental concerns. Continuous monitoring and adjustments are essential to avoid these pitfalls.

What Are the Benefits of Using a Continuous Coater in Manufacturing? - Applications of Continuous Coaters Across Different Industries

| Industry | Key Benefits | Common Applications |

|---|---|---|

| Pharmaceutical | Improved uniformity and dosage accuracy | Film coating of tablets and capsules |

| Food Processing | Enhanced product presentation and shelf life | Coating of snacks, candies, and cereals |

| Cosmetics | Consistency in product appearance and feel | Coating of powders and creams |

| Electronics | Protection against moisture and dust | Coating of circuit boards |

| Automotive | Durability and corrosion resistance | Coating of metal parts and components |

Related Posts

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process

-

Top 10 Essential Tablet Coating Machine Parts You Need to Know

-

How to Choose the Best Pharmaceutical Coating Machine for Your Needs

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

Why Coating Pan Tablets are Essential for Efficient Tablet Production

-

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process