Top Benefits of Using Continuous Coating Machines in Manufacturing Process

The manufacturing industry is constantly evolving, with advancements in technology paving the way for more efficient and effective processes. One such innovation is the continuous coating machine, a tool that has significantly transformed the way products are coated across various sectors. This machine ensures a smooth and uniform application of coatings, which is crucial for enhancing the quality and durability of products. By automating the coating process, manufacturers can achieve higher throughput and reduced labor costs, ultimately leading to improved productivity.

Moreover, continuous coating machines are designed to handle a variety of materials, making them versatile assets for manufacturers. They allow for precise control of coating thickness and consistency, which is essential for maintaining product standards. This flexibility not only aids in meeting diverse customer needs but also minimizes material waste, contributing to more sustainable manufacturing practices. As industries seek ways to optimize their processes and remain competitive, the adoption of continuous coating machines offers numerous benefits that are too significant to overlook.

Advantages of Continuous Coating Machines in Manufacturing

Continuous coating machines have revolutionized the manufacturing process, offering a wide array of advantages that significantly enhance efficiency and product quality. One of the primary benefits is the ability to achieve uniform coating over continuous production runs, ensuring that every product meets stringent quality standards. This level of consistency minimizes waste and reduces the need for rework, ultimately saving time and resources.

Another notable advantage is the increased production speed. Continuous coating machines can operate at a high throughput rate, allowing manufacturers to meet high demand without compromising quality. This efficiency is crucial in today’s fast-paced market, where quick turnaround times can give businesses a competitive edge. Additionally, the automation of the continuous coating process reduces manual labor, which not only decreases labor costs but also minimizes human error.

**Tip:** When considering the implementation of continuous coating machines, it is essential to assess the specific requirements of your production line. Taking the time to analyze factors such as material compatibility and desired coating thickness can help in selecting the right machine for optimal performance.

**Tip:** Regular maintenance of continuous coating machines cannot be overlooked. Scheduled inspections and timely servicing can prevent unexpected downtimes and extend the life of your equipment, ensuring that it consistently delivers high-quality results.

Top Benefits of Using Continuous Coating Machines in Manufacturing Process

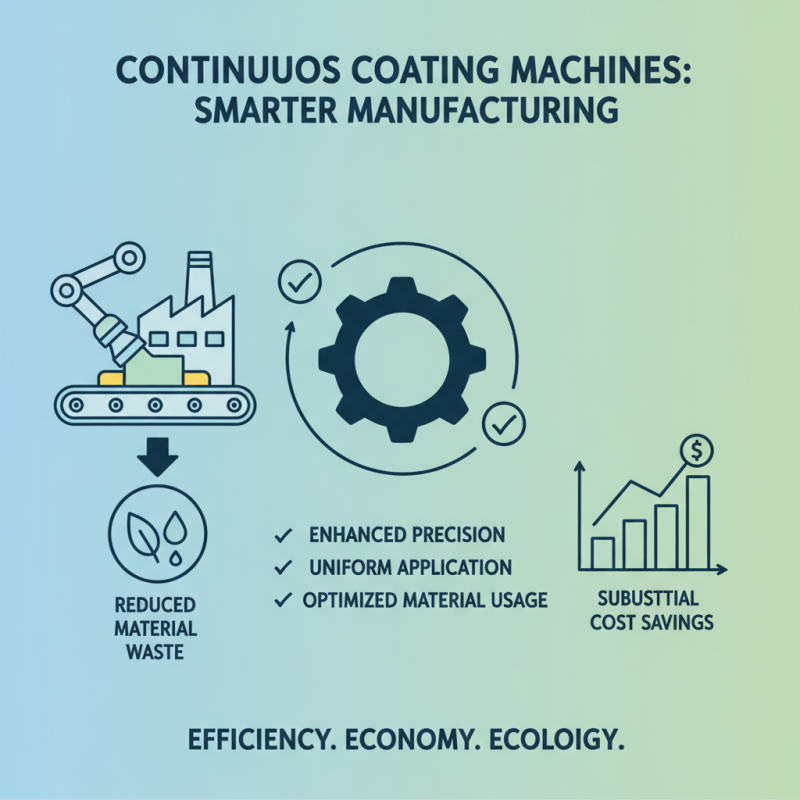

This chart illustrates the advantages of using continuous coating machines in manufacturing processes, showcasing key benefits such as efficiency, consistency, and reduced waste.

Increased Efficiency and Productivity in Coating Processes

The use of continuous coating machines in the manufacturing process significantly enhances efficiency and productivity in coating operations. Research indicates that processes employing continuous coating can improve production speeds by up to 50%, as they minimize downtime associated with traditional batch processing techniques. In an industry survey, 70% of manufacturers reported that utilizing continuous coating setups allowed for more consistent application of coatings, leading to fewer defects and reduced material waste.

To maintain high efficiency with continuous coating machines, it's essential to optimize the setup process. Regular calibration and maintenance of the machinery can prevent sluggish performance, ensuring that the coating process operates at its peak capacity. Additionally, incorporating advanced automation technologies can further streamline workflows, allow for real-time monitoring, and provide data analytics to enhance decision-making processes.

Tip: Regularly training your staff on the latest coating technologies and machine operations can significantly contribute to maximizing output and reducing errors. Keeping abreast of industry trends and innovations via professional workshops can equip your team with essential skills that drive productivity.

Consistent Quality and Uniform Coating Applications

In the manufacturing process, achieving consistent quality is paramount, especially when it comes to coating applications. Continuous coating machines play a pivotal role in this regard by ensuring a uniform application of materials across various surfaces. By maintaining a steady flow and optimized parameters, these machines minimize the risk of defects and variations, which can often lead to product failures or performance issues. This consistency not only enhances the overall quality of the final product but also builds customer trust and satisfaction.

Moreover, uniform coating applications facilitated by continuous coating machines contribute significantly to operational efficiency. With precise control over the coating thickness and material distribution, manufacturers can reduce waste and optimize resource usage. This reliability in the coating process allows for a streamlined production schedule, reducing downtime and increasing output. Ultimately, as manufacturers strive for excellence, the application of continuous coating technologies serves as a cornerstone for maintaining high standards of quality and efficiency in an increasingly competitive marketplace.

Reduced Material Waste and Cost Savings

The use of continuous coating machines in manufacturing processes offers significant advantages, especially in reducing material waste and achieving substantial cost savings. One primary benefit is the enhanced precision these machines provide, which allows for a more uniform application of coating materials. This precision minimizes the over-application of coatings, thereby drastically decreasing the amount of excess material that would otherwise go to waste. As a result, manufacturers can optimize their material usage, ensuring that every drop of coating is applied where needed, thus conserving resources and minimizing environmental impact.

Additionally, the efficiency of continuous coating machines leads to cost savings that extend beyond just material waste reduction. By streamlining the coating process, manufacturers can reduce production time, allowing for higher throughput and increased productivity. The improved efficiency also translates into lower labor costs, as fewer workers are needed to monitor and adjust the process. Together, these factors contribute to a more economical manufacturing operation, where the savings on materials and labor can significantly boost the bottom line. By investing in continuous coating technology, manufacturers can not only reduce waste but also enhance their overall operational efficiency.

Flexibility for Various Substrates and Coating Materials

Continuous coating machines have revolutionized the manufacturing landscape by providing unparalleled flexibility for various substrates and coating materials. According to a report from the Coating Manufacturers Association, the ability to process multiple substrate types—such as metals, plastics, and glass—has led to a significant reduction in setup times and waste, enhancing overall production efficiency by up to 30%. This adaptability is crucial as manufacturers strive to meet diverse customer demands and rapidly changing market trends.

In addition to substrate flexibility, these machines can handle a wide range of coating materials, including solvents, water-based coatings, and powder coatings. A study conducted by the National Association of Manufacturers indicates that the ability to switch between various coating types without extensive downtime increases throughput and reduces operational costs by approximately 20%. This versatility not only allows manufacturers to optimize their production lines but also enables them to innovate by experimenting with new coating materials and techniques, ultimately enhancing product quality and performance in competitive markets.

Top Benefits of Using Continuous Coating Machines in Manufacturing Process - Flexibility for Various Substrates and Coating Materials

| Benefit | Description | Applicable Substrates | Coating Materials |

|---|---|---|---|

| High Efficiency | Continuous operation leads to increased production rates and reduced downtime. | Metal, Plastic, Wood | Powder Coating, Liquid Coating |

| Versatility | Able to accommodate a variety of substrates and coating materials. | Glass, Textiles | Solvent-Based, Water-Based |

| Improved Quality | Consistent application results in higher-quality finished products. | Ceramics, Rubber | Electrostatic Coating, UV Coating |

| Reduced Waste | Efficient coating process minimizes overspray and material waste. | Various composites | Acrylic Coating, Epoxy Coating |

| User-Friendly Operations | Modern controls allow for easy adjustments and monitoring. | Foams, Paper | Custom Blends, Specialty Coatings |

Conclusion

The use of continuous coating machines in the manufacturing process offers significant advantages that enhance operational efficiency. These machines increase productivity by automating the coating process, allowing for faster production times while consistently delivering uniform coating applications. The precision of continuous coating machines ensures high-quality outputs with minimal variability, which is essential for maintaining standards in various industries.

Moreover, the implementation of these machines leads to reduced material waste, resulting in substantial cost savings. Their versatility allows manufacturers to work with various substrates and coating materials, adapting easily to changing requirements. Overall, continuous coating machines streamline operations, enhance automation, and contribute to a more efficient manufacturing process, making them a valuable investment for modern production facilities.

Related Posts

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality

-

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process

-

How to Choose the Best Film Coating for Your Projects and Applications

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery