Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process

In the fast-evolving world of pharmaceutical manufacturing, the efficiency of the coating process is crucial for product quality and consistency. A leading expert in this field, Dr. John Smith, a consultant at the Pharmaceutical Coating Institute, emphasizes that "the tablet coating pan is an essential tool that not only enhances the flavor and appearance of tablets but also significantly improves the bioavailability of the active ingredients." This statement underscores the pivotal role that tablet coating pans play in modern production environments.

Utilizing a tablet coating pan can lead to a variety of benefits, ranging from improved processing times to enhanced product performance. The versatility and design of these pans allow for uniform coating and optimal temperature control, making them ideal for achieving desired specifications. As manufacturers strive to meet increasing regulatory and consumer demands, understanding the advantages of tablet coating pans becomes more important than ever.

In this article, we will explore the top ten benefits of using a tablet coating pan, illustrating how this equipment contributes to a more efficient coating process. By delving into its features and advantages, manufacturers can harness the full potential of tablet coating technology, ultimately leading to higher-quality products and increased satisfaction in the marketplace.

Benefits of Tablet Coating Pans for Enhanced Efficiency

The use of tablet coating pans has become increasingly important in the pharmaceutical and food industries for enhancing production efficiency. One of the primary advantages of these pans is their ability to ensure uniform and consistent coating of tablets. This not only improves the quality of the end product but also minimizes the risk of defects that can lead to costly rework or waste. The controlled environment provided by the coating pan allows for better regulation of parameters such as temperature and moisture, resulting in a smoother and more uniform coat.

In addition to improving product quality, tablet coating pans significantly streamline the manufacturing process. They are designed to operate with high capacity, allowing for large batches of tablets to be processed in a relatively short timeframe. This increase in throughput translates to higher productivity and lower production costs. Furthermore, the automation capabilities of modern coating pans enable manufacturers to maintain precise control over the coating process, reducing the need for manual intervention and decreasing the potential for human error. Overall, incorporating tablet coating pans into the production line leads to enhanced efficiency, making this equipment an invaluable asset for manufacturers seeking to optimize their operations.

Top 10 Benefits of Using a Tablet Coating Pan

Streamlining the Coating Process with Tablet Coating Technology

Tablet coating technology has revolutionized the pharmaceutical and nutraceutical industries by providing a streamlined approach to the coating process. Utilizing a tablet coating pan allows for even distribution of coating materials, ensuring that each tablet receives a consistent layer. This uniform application is essential not only for the aesthetic appeal of the tablets but also for enhancing their functionality, such as improving stability, taste masking, and controlled-release properties.

Incorporating tablet coating pans also significantly improves operational efficiency. The design of the pan enables effective mixing, reducing the time and effort required for the coating process. Manufacturers can achieve higher production rates while maintaining quality control, which is crucial in competitive markets. Additionally, the technology minimizes waste of coating materials, making it a more cost-effective solution overall. This efficiency translates into a faster turnaround for production cycles, allowing companies to respond quickly to market demands without compromising on quality.

Improving Coating Uniformity with Tablet Coating Pans

Tablet coating pans are essential for achieving high coating uniformity in the pharmaceutical and nutraceutical industries. One of the key advantages of using these pans is their ability to provide an even, consistent coating on tablets, which is crucial for both efficacy and consumer satisfaction. The design of the coating pan allows for optimal airflow and heat distribution, ensuring that the coating material adheres uniformly to the tablet surfaces. This uniformity is essential in preventing issues such as uneven release profiles or localized degradation of the active ingredients.

Moreover, tablet coating pans are engineered to maintain precise control over the coating process parameters, such as temperature, humidity, and spray rate. This level of control enhances the likelihood of achieving a high-quality coating with minimal variations. The ability to adjust these parameters in real-time allows operators to respond quickly to any changes in the coating dynamics, ensuring a consistent and uniform layer on every batch. As a result, manufacturers can produce tablets that not only meet regulatory standards but also provide enhanced performance and user experience.

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process - Improving Coating Uniformity with Tablet Coating Pans

| Benefit | Description | Impact on Coating Uniformity |

|---|---|---|

| Enhanced Control | Allows precise control over coating conditions leading to uniform coatings. | Increases consistency across batch production. |

| Reduced Production Time | Accelerates the coating process through optimized airflow and distribution. | Shortens time from production to market. |

| Minimized Material Wastage | Efficient use of coating materials limits excess waste. | Improves cost efficiency in production. |

| Versatile Coating Options | Supports various types of coatings including sugar, film, and enteric. | Enhances formulation flexibility. |

| Improved Tablet Quality | Ensures uniform layer thickness which enhances tablet integrity. | Reduces the risk of tablet defects. |

| Better Solvent Control | Utilizes closed systems for solvent recovery. | Improves environmental compliance and safety. |

| Ease of Cleaning | Designed for quick disassembly and cleaning. | Enhances turnaround time between batches. |

| Consistent Batch Results | Facilitates reproducibility of results across different production runs. | Solidifies brand reliability. |

| Enhanced Safety Features | Incorporates safety mechanisms to reduce operator exposure. | Promotes a safer working environment. |

| Data-Driven Monitoring | Equipped with sensors for real-time data collection. | Allows for proactive adjustments to improve coating uniformity. |

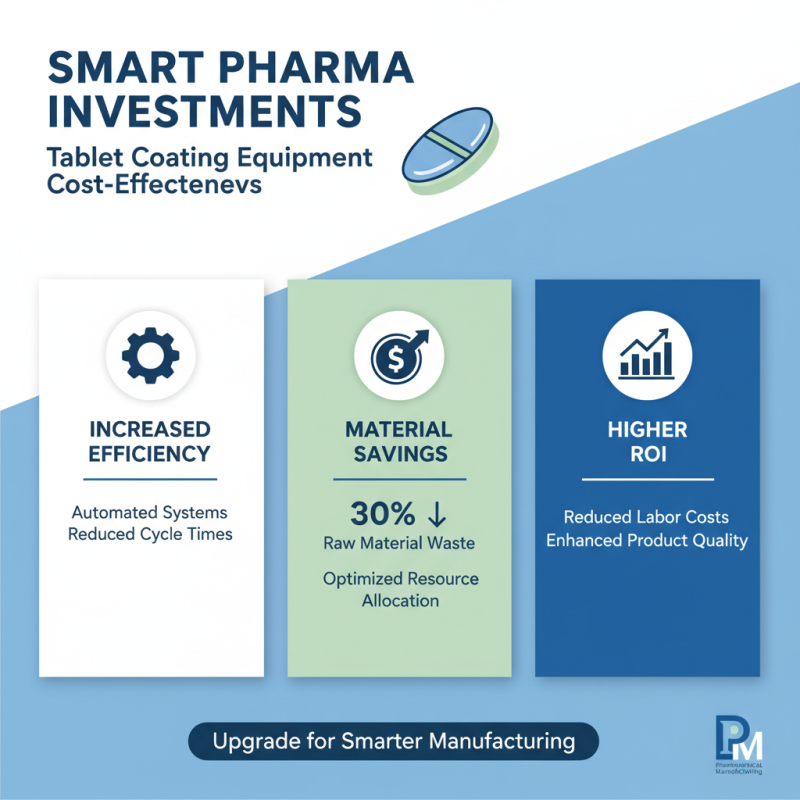

Cost-Effectiveness of Using Tablet Coating Equipment

The cost-effectiveness of using tablet coating equipment is a critical consideration for pharmaceutical manufacturers. By investing in advanced tablet coating pans, companies can achieve significant savings in material costs and labor through increased efficiency. According to a recent industry report, organizations that upgraded to automated coating systems reported a 30% reduction in raw material waste, enabling them to allocate resources more effectively and achieve a higher return on investment.

Moreover, leveraging tablet coating pans can streamline production timelines. The ability to coat tablets uniformly and consistently minimizes the risk of defects, which consequently reduces the costs associated with rework and quality control processes. A study showed that manufacturers implementing modern coating technologies experienced a 25% enhancement in throughput, allowing for larger batch productions without sacrificing quality. This efficiency translates not only to faster market delivery but also to increased profitability.

**Tips:** When selecting tablet coating equipment, consider investing in models that offer adjustable parameters for different coating solutions. This flexibility allows for the optimization of various formulations and can lead to further cost reductions over time. Additionally, training your staff to utilize the equipment effectively can maximize operational efficiency and minimize errors. Regular maintenance of the coating pans also ensures longevity and optimal performance, aiding in maintaining overall cost-effectiveness.

Ease of Use and Maintenance in Tablet Coating Systems

The ease of use and maintenance of tablet coating systems play a pivotal role in enhancing production efficiency and ensuring high-quality coating outcomes. A well-designed tablet coating pan is user-friendly, which translates to reduced operator training time and improved operational efficiency. According to a report by the International Society for Pharmaceutical Engineering (ISPE), streamlined equipment can cut down setup times by up to 25%, allowing for faster production cycles. These efficiencies are particularly beneficial in environments where speed-to-market is essential.

Furthermore, the maintenance aspect of tablet coating systems cannot be overlooked. Simple disassembly and reassembly processes for cleaning can significantly reduce downtime. A study published in the Journal of Pharmaceutical Innovation highlights that operators reported a decrease in maintenance-related halts by nearly 30% when using modern coating pans that feature easy access design principles. Regular upkeep is crucial to maintain not only the machinery but also the integrity of the coatings applied. By implementing systems that prioritize ease of use and maintenance, pharmaceutical manufacturers can achieve both operational excellence and consistent product quality.