How to Choose the Best Perforated Pan Coating Machine for Your Business

Choosing the right perforated pan coating machine for your business can be challenging. The market is filled with various options, each claiming to be the best. It’s essential to understand what features matter most for your production needs. A good coating machine should enhance efficiency and reduce waste.

Consider the capacity and speed of the machine. Some models focus on high output, while others may offer better precision. You must reflect on what aligns with your production goals. Reliability is another crucial factor. Machines that frequently break down can slow your operation.

Don't overlook the importance of after-sales support. A manufacturer that stands by their product will be invaluable. You might find options that seem perfect but lack customer service. In conclusion, investing time in research will help you make an informed choice about your perforated pan coating machine.

Importance of Perforated Pan Coating in Food Processing

Perforated pan coating plays a crucial role in the food processing industry. This technique ensures even distribution of coatings on food products. It enhances flavors, improves texture, and extends shelf life. When executed properly, it can elevate the overall quality of food items significantly. Many manufacturers notice differences in taste and appearance after using such methods.

Choosing the right perforated pan coating machine is essential. The machine should cater to specific food types and production volume. It's important to consider the coating materials being used, as some might require special machinery. A machine that is easy to clean will save time. However, it may not always be easy to find the right balance between efficiency and functionality.

Some businesses face challenges in this process. They may struggle with inconsistent coating thickness or uneven application. This can lead to waste and inconsistencies in product quality. The choice of machine can contribute to these issues. Investing in the right technology may require deeper analysis. Keep in mind that trial and error can be part of the journey to perfecting production processes.

Key Features to Look for in a Perforated Pan Coating Machine

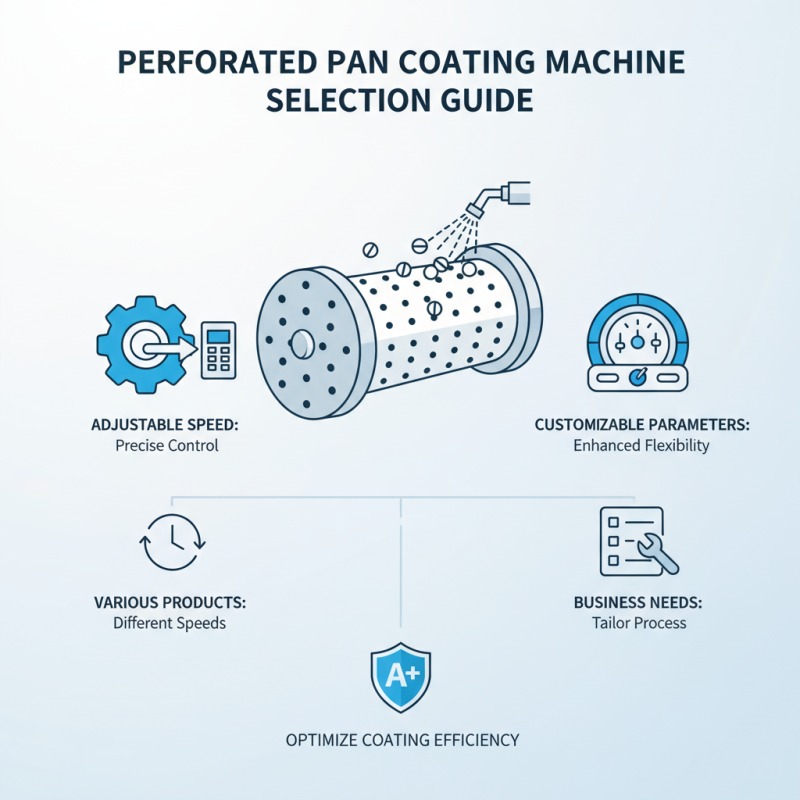

When selecting a perforated pan coating machine, focus on the key features that suit your business's needs. Look for adjustable speed settings. These settings allow precise control over the coating process. You may need different speeds for various products. A machine with customizable parameters offers flexibility.

Consider the material of the machine. Stainless steel is often a good choice for durability. It resists corrosion and is easy to clean. Look for models with smooth surfaces to prevent cross-contamination. However, keep an eye on the weight of the machine. Heavier models may provide stability but could complicate movement and maintenance.

Pay attention to the user interface. A straightforward control panel can save time during operation. Make sure operators find it intuitive. Some machines offer automated features; these can reduce labor costs but may require training. Balance automation with hands-on approaches to ensure quality. Your decision should enhance efficiency without compromising product standards.

Understanding Different Types of Coating Technologies

When selecting a perforated pan coating machine, it's essential to understand the various coating technologies available. Each technology offers unique benefits and challenges. For instance, electrostatic coating is known for its efficiency and uniformity, but it requires precise adjustments. Manual adjustments can lead to inconsistencies, which could affect production quality. Many manufacturers must weigh the cost of mistakes against the supposed efficiency.

Another popular method is dip coating. This technique allows for a thorough coverage of surfaces. However, it can lead to excess material leftover, which increases costs. Balancing waste management with effective coating remains tricky for many. It’s crucial to find a method that aligns with specific production needs while considering environmental impacts.

Lastly, spray coating is versatile and adaptable. It offers flexibility for different products. However, achieving the right spray pattern can be challenging. Consistency in application is vital, yet often elusive. Investing in training or advanced technology may be necessary. Evaluating these methods ensures that the chosen machine fits the business goals and helps improve overall performance.

Evaluating Machine Capacity and Efficiency for Business Needs

When selecting a perforated pan coating machine, evaluating capacity and efficiency is crucial. A machine's capacity affects production volume directly. For instance, a machine with a capacity of 1,500 units per hour can significantly enhance output. This keeps pace with growing demand in various industries, especially food production. Studies indicate that an increase in machine efficiency can lead to a 20% reduction in operational costs.

Consider the machine's compatibility with your production line. If it can't integrate smoothly, it creates bottlenecks. The layout of the machine matters too. A poor design can lead to wasted space and time. According to recent industry reports, 30% of manufacturers face challenges with inefficient layouts.

Efficiency also relates to maintenance needs. Machines requiring frequent repairs disrupt production schedules. Ideally, select models that offer reliability. Look for user data indicating lower downtime rates. However, it’s essential to reflect on your unique business needs. Not every high-capacity machine is suitable. Sometimes, less is more, allowing for better quality control.

How to Choose the Best Perforated Pan Coating Machine for Your Business - Evaluating Machine Capacity and Efficiency for Business Needs

| Model | Capacity (kg/hr) | Efficiency (%) | Energy Consumption (kW) | Dimensions (LxWxH in cm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 200 | 90 | 15 | 150x100x200 | 120 |

| Model B | 300 | 85 | 20 | 180x120x250 | 150 |

| Model C | 150 | 92 | 12 | 140x90x180 | 100 |

| Model D | 250 | 88 | 18 | 160x110x230 | 130 |

Maintaining and Servicing Your Perforated Pan Coating Machine

Maintaining a perforated pan coating machine is crucial for optimal performance. Regular maintenance prevents defects and ensures consistent quality. Start with daily checks. Inspect for wear and tear. Look at belts, gears, and electrical connections. A small issue can lead to major breakdowns.

Cleaning the machine is vital. Residue buildup can affect operations. Use appropriate cleaning agents. Make sure to follow safety protocols. Neglecting this can cause inefficiencies. Consider setting a schedule for deep cleaning. This can help avoid last-minute rush jobs that lead to oversights.

Servicing your machine requires attention to detail. Train staff to identify irregularities. They should report any strange noises or unusual behavior. Investing in training saves money in the long run. Often, teams overlook the importance of good communication. Remember, minor issues can escalate into major problems. Regular servicing can enhance the lifespan of your coating machine.

Performance Metrics of Perforated Pan Coating Machines

Related Posts

-

Ultimate Guide to Perforated Pan System Benefits and Applications in Cooking

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

Top 10 Tablet Coating Machine Parts You Need for Maximum Efficiency

-

How to Choose the Best Film Coating for Your Projects and Applications

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process