How to Choose the Best Tablet Coating for Optimal Protection and Longevity

Choosing the right tablet coating is vital for ensuring the longevity and protection of your device. With a variety of options available on the market, understanding the differences and benefits of each coating can be crucial to making an informed decision. A well-selected tablet coating not only enhances the durability of your device but also contributes to maintaining its aesthetic appeal, thereby extending its lifespan.

In recent years, advancements in technology have led to the development of innovative tablet coatings that provide better protection against scratches, dust, and moisture. This advancement raises important questions about which coating is best suited for your specific needs. Whether you use your tablet for work, leisure, or education, selecting the optimal tablet coating can safeguard your investment from everyday wear and tear.

In this guide, we will explore the various types of tablet coatings available, their respective advantages, and considerations to keep in mind while choosing the right one for your device. By understanding how to choose the best tablet coating, you can enjoy your device to the fullest while ensuring it remains in pristine condition for years to come.

Understanding Tablet Coatings: Types and Functions

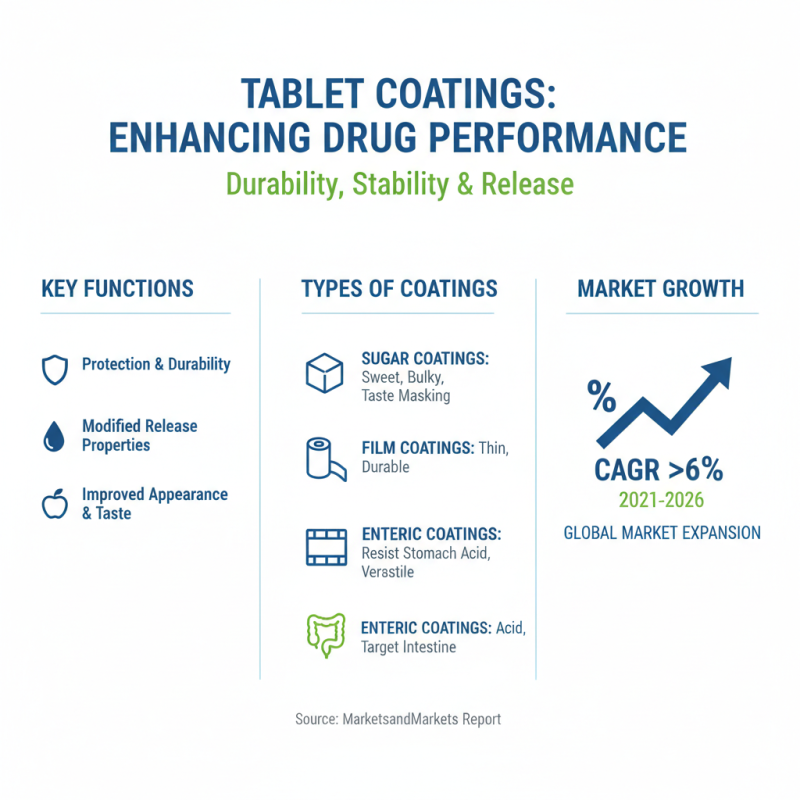

Tablet coatings play a crucial role in determining the durability and performance of pharmaceutical tablets. Various types of coatings serve specific functions, enhancing not only the tablet's appearance but also its stability and release properties. Common types of coatings include sugar coatings, film coatings, and enteric coatings. According to a report by MarketsandMarkets, the global market for tablet coatings is expected to grow at a CAGR of over 6% between 2021 and 2026, underscoring the increasing importance of these coatings in drug formulation.

Film coatings, for instance, are widely utilized due to their ability to protect the active pharmaceutical ingredients (APIs) from environmental factors such as moisture and light, which can degrade efficacy. Research indicates that film coatings can improve tablet shelf life by as much as 50%, illustrating their impact on product longevity. In addition, enteric coatings are designed to withstand stomach acid, ensuring that the tablet passes into the intestine before dissolving, which is critical for drugs that are better absorbed in that environment. This targeted release can significantly enhance therapeutic outcomes.

Understanding the specific requirements of a drug formulation is essential when choosing the appropriate tablet coating. Factors such as the desired release profile, environmental stability, and patient compliance must all be considered. With the continuous advancements in coating technologies, manufacturers now have access to more sophisticated materials and methods that cater to these varied needs, enabling the development of more effective and patient-friendly tablets.

Evaluating Material Durability: Key Factors in Coating Selection

When evaluating material durability for tablet coatings, several key factors should be taken into consideration. First and foremost is the resistance to scratches and abrasions, which can significantly impact the longevity of the device. A coating that offers excellent hardness can protect the tablet's surface from daily wear and tear, ensuring that it remains visually appealing and functional over time. Additionally, it is essential to consider the environmental conditions that the tablet may encounter, such as exposure to extreme temperatures, humidity, and potential chemical interactions. A coating designed to withstand these elements will provide enhanced durability and reliability.

Another critical factor in the coating selection process is its adhesion properties. A coating that adheres well to the substrate will not only enhance durability but also reduce the likelihood of peeling or delamination over time. Moreover, ease of application and maintenance is important; coatings that allow for simple cleaning and maintenance contribute to the device's long-term usability. Finally, the weight and thickness of the coating can affect the tablet's overall performance. A well-balanced coating provides optimal protection without compromising the device’s portability and functionality, ensuring that users can enjoy their tablets for years to come.

Assessing Environmental Resistance: Protection Against Elements

When selecting a tablet coating, the assessment of environmental resistance is crucial for ensuring both protection against elements and the longevity of the device. Various environmental factors such as humidity, temperature extremes, UV exposure, and chemical exposure can significantly impact the durability of tablets. According to a report by the International Electrotechnical Commission (IEC), tablets that feature advanced coatings can have up to 50% greater resistance to liquid damage and environmental deterioration compared to uncoated models.

Moreover, the rise in adoption of tablets for outdoor and industrial applications necessitates a focus on specific coatings that provide enhanced protection. Data from a recent market intelligence report highlighted that coatings incorporating nanotechnology can improve scratch resistance by 30%, while also offering superior repellency against water and other liquid substances. This advancement not only helps in maintaining the aesthetic appeal of the device but also ensures that the functionality remains uncompromised under various conditions.

Furthermore, coatings that protect against UV degradation are particularly important for users in sunny environments. Research suggests that tablets with UV-resistant coatings can last up to four times longer than those without such protection when exposed to direct sunlight. By prioritizing the environmental resistance attributes of tablet coatings, consumers can make informed decisions that extend the lifespan of their devices while safeguarding them from the challenging elements they may face.

How to Choose the Best Tablet Coating for Optimal Protection and Longevity - Assessing Environmental Resistance: Protection Against Elements

| Coating Type | Water Resistance | Scratch Resistance | UV Resistance | Chemical Resistance | Longevity |

|---|---|---|---|---|---|

| Hydrophobic Coating | Excellent | Moderate | Good | Fair | 3-5 years |

| Oleophobic Coating | Good | Excellent | Fair | Good | 2-4 years |

| Hard-Coat Anodizing | Fair | Excellent | Good | Excellent | 5-10 years |

| Nano-Coating | Excellent | Good | Excellent | Good | 3-7 years |

| Ceramic Coating | Good | Excellent | Excellent | Excellent | 10+ years |

Application Techniques: Methods for Optimal Coating Effectiveness

When it comes to selecting the best tablet coating for optimal protection and longevity, the application techniques you employ are critical to achieving effectiveness. According to a report by the Coatings Research Institute, improper application methods can reduce the durability and performance of protective coatings by up to 40%. Therefore, understanding the right techniques is essential. One recommended method is spray application, which not only provides an even coat but also allows for better penetration into the surface layer. This technique is particularly effective in achieving a uniform application, which helps to mitigate the risk of peeling and chipping over time.

Another effective application technique is brushing, often utilized for more intricate surfaces requiring precision. Data from the National Coating Association indicates that brushing can yield about 30% more material adherence compared to other methods, especially on porous surfaces. To maximize the benefits of either method, surface preparation is key. A clean and well-prepared substrate enhances adhesion rates significantly, as highlighted in a study published by the International Journal of Surface Science, which found that pre-treatment can improve coating durability by over 50%. By paying attention to these application techniques, you can ensure that your chosen coating delivers the best possible protection and extends the life of your tablet device.

Maintenance Tips: Ensuring Longevity of Tablet Coatings

When it comes to ensuring the longevity of tablet coatings, regular maintenance is paramount. Studies indicate that properly maintained coatings can extend the lifespan of devices by an average of 30%, revealing the significant impact of care routines (Industry Research Report, 2022). One crucial aspect of maintenance is the cleaning process. Utilizing non-abrasive, microfiber cloths and gentle cleaning solutions can help to prevent scratches and preserve the integrity of the coating. Manufacturers recommend a cleaning schedule that varies based on usage but suggest doing so at least once a week to minimize smudging and residue buildup.

In addition to cleaning, the way users handle and store their tablets can greatly influence the durability of the coating. According to a report from the Electronic Device Protection Association, improper handling, such as dropping devices or exposing them to extreme temperatures, can lead to accelerated wear and tear on coatings. Utilizing protective sleeves and avoiding excessive pressure on screens can mitigate these risks. Furthermore, applying a screen protector specifically designed for enhancing the lifetime of tablet coatings has been shown to reduce the incidence of damage by up to 50%, offering an additional layer of protection that complements regular maintenance routines.