How to Choose the Best Pharmaceutical Coating Machine for Your Needs

In the rapidly evolving pharmaceutical industry, the choice of equipment plays a crucial role in ensuring product quality and process efficiency. When it comes to manufacturing solid dosage forms, the selection of the right pharmaceutical coating machine is of paramount importance. Dr. Jane Smith, a renowned expert in pharmaceutical manufacturing, emphasizes, "The effectiveness of a coating process hinges not only on the machinery but also on understanding the specific needs of your production line." This highlights the necessity for thorough analysis when selecting a coating machine tailored to meet the unique requirements of your operations.

Pharmaceutical coating machines serve a vital function in enhancing the stability, bioavailability, and appearance of drugs. With a plethora of options available, it can be overwhelming for manufacturers to pinpoint the most suitable machine for their specific needs. Factors such as batch size, type of coating, and production speed could significantly influence the decision-making process. Understanding these parameters is essential for optimizing production while adhering to regulatory standards and ensuring safety.

Therefore, choosing the right pharmaceutical coating machine is not merely about picking the latest technology; it involves strategic consideration of various operational demands and outcomes. Through careful evaluation and informed choices, manufacturers can elevate their production capabilities, ultimately leading to improved patient outcomes and business success.

Understanding the Different Types of Pharmaceutical Coating Machines

When selecting a pharmaceutical coating machine, it is crucial to understand the distinct types of machines available in the market, as each serves unique needs based on the production scale and coating requirements. The primary categories include pan coaters, fluid bed coaters, spray coaters, and direct compression coaters. Pan coaters are commonly used for small to medium batch sizes and are known for their versatility in coating various types of tablets and granules. A report by Research and Markets indicated that the global pan coating machine market is projected to grow significantly, emphasizing its sustained demand in the pharmaceutical industry.

Fluid bed coaters, on the other hand, are favored for their efficiency and uniformity in coating, often used in larger-scale operations. They utilize fluidization technology to achieve a consistent coating layer, making them ideal for applications requiring precise control of coating thickness. According to a market analysis by Transparency Market Research, the fluid bed equipment segment is anticipated to witness notable growth, driven by increasing demand for advanced coating solutions that enhance drug release profiles.

Spray coaters are also gaining traction, particularly in specialized pharmaceutical applications where targeted release mechanisms are essential. These machines enable precise application of coating materials, catering to specific formulations and complex drug delivery systems. With the rising trend of personalized medicine, the flexibility offered by spray coating technology is expected to drive its market growth, as highlighted in various industry forecasts. Understanding these types of pharmaceutical coating machines is vital for manufacturers to select the right technology that meets their specific production requirements and accelerates innovation in drug formulations.

How to Choose the Best Pharmaceutical Coating Machine for Your Needs

| Type of Coating Machine | Main Features | Benefits | Typical Applications |

|---|---|---|---|

| Pan Coating Machine | Rotating pan, spray system for uniform coating | Cost-effective, easy to operate, suitable for small to medium batches | Coating tablets and granules |

| Film Coating Machine | Automated spray system, precise film thickness control | High efficiency, uniform coating, suitable for high production volumes | Pharmaceutical tablets, nutraceuticals |

| Sugar Coating Machine | Multi-step process, sugar syrup application | Excellent taste masking, aesthetic appeal | Candy coatings, certain types of tablets |

| Drum Coating Machine | Fixed or rotating drum design, manual or automatic | Versatile, adaptable for various coating solutions | Bulk materials, granules, pellets |

| Fluid Bed Coater | Fluidized bed technology, uniform air distribution | Highly uniform coating, ideal for heat-sensitive materials | Tablets, granules, beads |

Key Factors to Consider When Selecting a Coating Machine

When selecting a pharmaceutical coating machine, it is crucial to consider several key factors to ensure it meets your specific manufacturing needs. One of the primary considerations is the type of coating process required, such as sugar coating, film coating, or enteric coating. Each process demands different machine capabilities and configurations. According to a recent market report by Grand View Research, the global pharmaceutical coating systems market is expected to reach USD 2.7 billion by 2027, indicating the increasing demand for efficient and adaptable coating technologies.

Another essential factor is the production capacity of the machine. Assessing the throughput capability helps in aligning equipment with manufacturing goals, ensuring minimal downtimes and optimal efficiency. Machines should be capable of handling the varying batch sizes based on production requirements. A report from MarketsandMarkets suggests that advancements in automation and technology are pivotal in enhancing production capacity, allowing for better scalability in coating operations.

**Tips:** When evaluating potential machines, prioritize those offering easy maintenance and cleaning features. Efficient cleaning protocols can significantly reduce downtime and improve overall productivity. Additionally, consider machines equipped with advanced monitoring systems to ensure consistent quality during the coating process. Investing in machines with adaptable features will offer flexibility as product formulations evolve over time.

Key Factors to Consider When Selecting a Coating Machine

Evaluating Machine Efficiency and Production Capacity

When selecting a pharmaceutical coating machine, understanding its efficiency and production capacity is crucial for meeting operational demands.

Industry reports indicate that the global pharmaceutical machinery market is projected to reach USD 12.8 billion by 2026, growing at a CAGR of approximately 6.9% from 2021 to 2026.

This growth underscores the increasing importance of advanced technologies in achieving high throughput and precision in pharmaceutical manufacturing processes.

Machine efficiency can be quantified through metrics such as cycle time and downtime.

A recent study revealed that well-optimized coating machines can achieve cycle times as low as 30 minutes per batch for immediate release tablets, significantly reducing overall production times.

Additionally, the integration of IoT technologies allows for real-time monitoring of machine performance, which can improve operational efficiency by up to 20% by minimizing unplanned downtimes.

As production capacity is equally influenced by batch size and output rate, manufacturers should carefully evaluate the machine's specifications to ensure it aligns with their production goals and scale.

Furthermore, the adaptability of the coating machine to different processes, such as aqueous and non-aqueous coatings, enhances its utility across a range of product types.

According to industry insights, machines capable of seamlessly transitioning between various coating methods can increase production flexibility, thereby accommodating fluctuating market demands without compromising efficiency.

By prioritizing these factors, pharmaceutical manufacturers can select the optimal coating solution that aligns with their operational needs and growth objectives.

Assessing Compatibility with Your Production Requirements

When selecting a pharmaceutical coating machine, assessing compatibility with your production requirements is crucial. A report by the International Society for Pharmaceutical Engineering indicates that nearly 60% of production downtime is attributed to equipment inefficiencies. Therefore, understanding the specific needs of your production line can significantly enhance productivity and reduce costs. Start by evaluating the scale of your operation; smaller batches may require versatile machines with easier setup times, while large-scale operations benefit from high-capacity systems designed for continuous production.

Additionally, consider the types of products being coated. According to a study published by the American Pharmaceutical Review, the demand for various coating methods, such as film and sugar coatings, varies by product type and market trends. For instance, film coatings have seen a 25% increase in preference among manufacturers due to their effectiveness in taste masking and improving stability. As such, a coating machine that offers flexibility in application methods can be advantageous.

Ultimately, aligning the specifications of the coating equipment with your production goals—such as batch size, coating type, and operational efficiency—will be instrumental in achieving optimal results and meeting market demands.

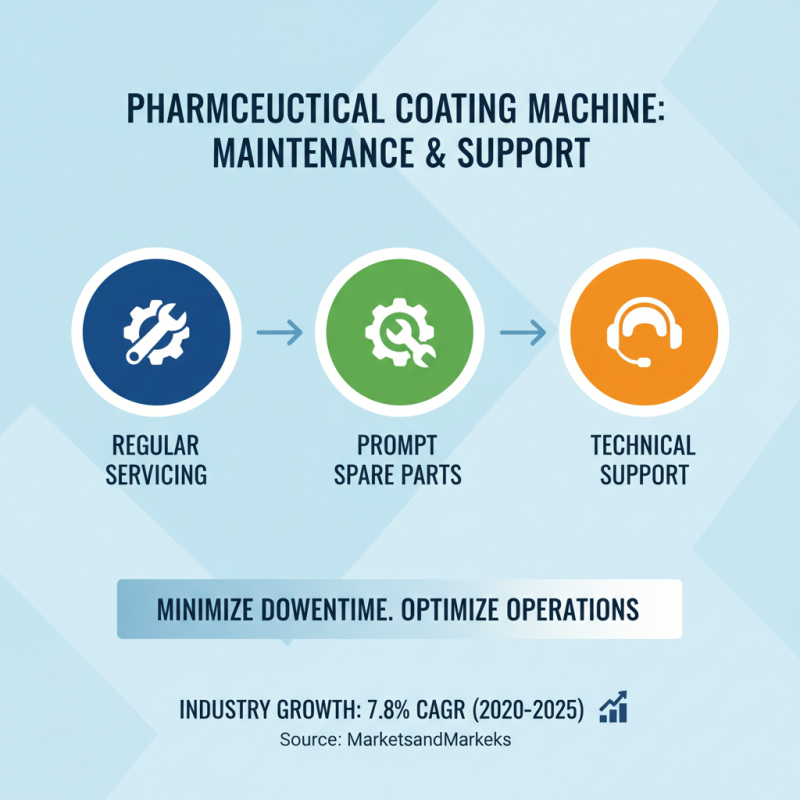

Maintenance and Support Options for Coating Machines

When opting for a pharmaceutical coating machine, understanding the maintenance and support options available is critical to ensuring long-term efficiency and productivity. According to a recent industry analysis published by MarketsandMarkets, the global pharmaceutical manufacturing equipment market is projected to grow at a CAGR of 7.8% from 2020 to 2025, emphasizing the increasing importance of reliable maintenance in the industry. Regular servicing, prompt access to spare parts, and ongoing technical support are essential to minimize downtime and optimize operations.

Furthermore, a well-established maintenance strategy can significantly enhance the lifespan of coating machines. The International Society for Pharmaceutical Engineering (ISPE) suggests implementing a preventive maintenance program, which could lead to a 30% reduction in maintenance costs and a 20% increase in the overall equipment effectiveness (OEE). Establishing a relationship with knowledgeable service providers who understand the nuances of pharmaceutical equipment can also ensure compliance with stringent regulatory requirements, safeguarding both production quality and operational integrity. Regularly scheduled training for staff is equally crucial, as it empowers operators to efficiently troubleshoot common issues and maintain optimal machine performance, thus maximizing productivity in the long run.

Related Posts

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process

-

Top 10 Tips for Choosing the Right Pharma Coating Machine for Your Needs

-

Why Coating Pan Tablets are Essential for Efficient Tablet Production

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

Top 10 Essential Tablet Coating Machine Parts You Need to Know

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality