How to Choose the Right Coating Machine for Tablet Production?

Choosing the right coating machine tablet is crucial in the pharmaceutical industry. The right equipment impacts production quality and efficiency. There are many options available, each with unique features. Finding the best fit may be challenging.

Consider your specific needs. Different tablet formulations may require distinct coating processes. The size and scale of production also play a role. A machine suitable for small batches may not work for larger operations. Pay attention to the complexity of your requirements.

A thorough evaluation of available coating machines is important. Look for machines that offer flexibility for future changes. Don't overlook service support and maintenance. Your decision should factor in not just current needs but also potential growth. Reflect on the cost versus benefits as well. Careful consideration will lead to better outcomes in tablet production.

Understanding Different Types of Coating Machines for Tablets

Choosing the right coating machine for tablet production is crucial. There are various types available, each with unique features. Understanding these can be complex. Let's break down the main options.

One common type is the pan coater. This machine uses a rotating pan to coat tablets with liquids. It’s versatile and often used for sugar coating. However, achieving uniformity can sometimes be a challenge. Operators may need extra training to handle the variations in process settings.

Another option is the bottom-spray coater. This design sprays the coating solution from the bottom, allowing for even coverage. It is efficient but can lead to overspray issues. Clean-up might not be as straightforward. Some users report difficulties in maintaining the equipment.

Lastly, the fluid bed coater is also popular. It employs hot air to coat tablets while moving them. This offers excellent control over the coating process. Yet, it’s vital to monitor temperature closely. Too high a temperature can degrade the tablet. Each type of machine has pros and cons. Reflecting on your specific needs helps in making the right choice.

Understanding Different Types of Coating Machines for Tablet Production

This chart displays the comparison of different types of coating machines used in tablet production, showcasing their efficiency and features.

Factors to Consider When Selecting a Coating Machine

Choosing a coating machine for tablet production is crucial. Several important factors influence this decision. The size and scale of production play a key role. A small facility may benefit from a compact machine. Larger operations often require more robust solutions.

Next, consider the type of coating. Different processes deliver varying results. Some methods offer better film adherence. Others provide a smoother finish. This choice should align with the product's desired outcome. Examine features like coating uniformity and drying time as well. These elements impact overall efficiency.

Lastly, budget constraints can affect your selection. Higher quality machines often come with a heftier price tag. Assess whether the investment matches your production goals and expected returns. It's essential to reflect on these challenges while making your choice. Finding the right balance may take time.

Evaluating Production Capacity and Efficiency Requirements

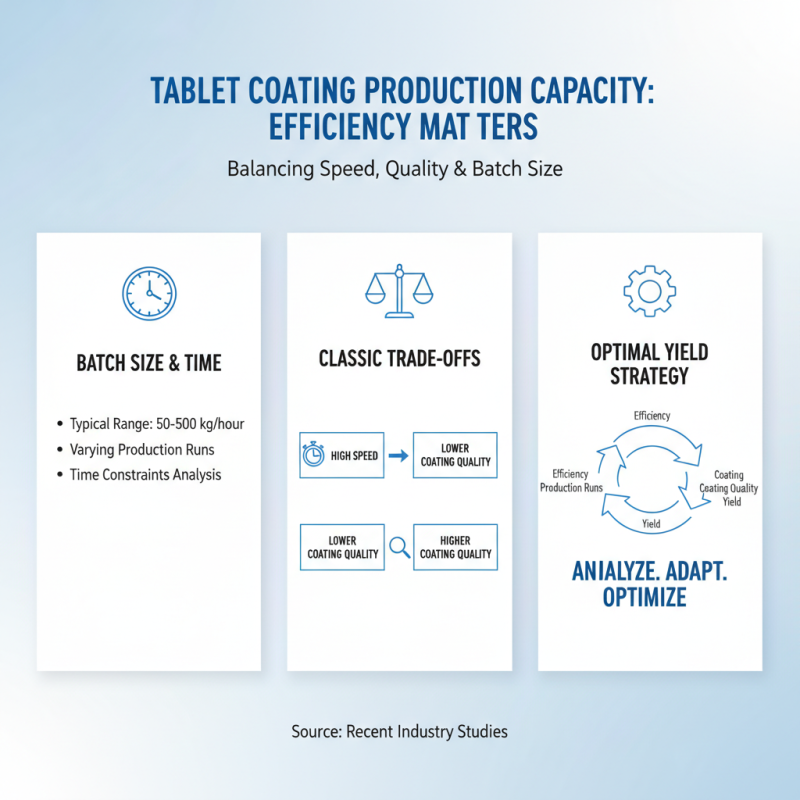

When evaluating production capacity for tablet coating, efficiency is crucial. Recent industry studies show that machines need to handle varying batch sizes, often ranging from 50 to 500 kg per hour. This requires a careful analysis of both the size of the production runs and the time constraints involved. A classic approach suggests that achieving a high yield often means accepting trade-offs in speed and quality. For example, a high-speed machine may operate at a lower coating quality compared to a slower, more precise option.

Efficiency also encompasses energy and material use. Reports indicate that the right coating machine can reduce solvent use by up to 30%, enhancing not only cost-effectiveness but also environmental sustainability. Inadequate attention to these factors can lead to excess waste and increased operational costs. Studies reveal that nearly 15% of production failures are associated with improper equipment choice, pointing to the need for meticulous assessment.

As production requirements evolve, it's essential to adapt coating processes accordingly. Machines that are too bulky may become inefficient for smaller runs. Consideration of flexibility in machine design can lead to better results. The push for higher efficiency cannot ignore the balance between capacity and the quality of the final product. A reflective approach to capacity planning is necessary to avoid potential pitfalls. Adjustments may be required as production demands shift over time.

Assessing Coating Technique and Technology Options

Choosing the right coating machine for tablet production involves evaluating various techniques and technologies. Different coating methods can significantly affect the product quality. Common techniques include pan coating, spray coating, and fluidized bed coating. Each method has unique benefits and limitations. You'll need to consider factors like coating uniformity and drying efficiency.

Tip: Examine the tablet composition. The materials will influence the choice of coating technology. For example, sensitive compounds may require gentle handling.

Fluidized bed coaters are increasingly popular. They provide uniform coverage and control over thickness. However, they may require more maintenance than simpler machines. It's crucial to assess your production volume and frequency of changeovers. Multiple formulations can complicate the coating process.

Tip: Always review technical specifications before purchase. Understand the operational limits and capabilities of the equipment.

Lastly, consider scalability. Some coating solutions work well for small batches but struggle with larger volumes. This limitation can lead to inefficiencies. A careful evaluation of your needs against available options is essential. It’s important to remember that what works today may not suit future demands. Adjusting your strategy based on production growth is vital.

Budgeting and Cost Analysis for Coating Machine Acquisition

When considering a coating machine for tablet production, budgeting is crucial. You need to assess the costs involved. Start by defining your budget range. This helps in narrowing down options. Evaluate initial costs versus long-term value. A cheaper machine may lead to higher maintenance costs later.

Analyze the total cost of ownership. Factors like energy consumption and operational efficiency matter significantly. A machine that uses less energy can save substantial amounts over time. Factor in training and support costs as well. Staff may require training to operate new machines efficiently.

It's also essential to think about potential scalability. As production needs grow, will the machine meet future demands? You might need to upgrade sooner than expected. Reflect on your business goals and select a machine that supports them. Balancing cost and quality can be challenging but necessary for sustainable operations.

Related Posts

-

Why Coating Pan Tablets are Essential for Efficient Tablet Production

-

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

Top 10 Tablet Coating Machine Parts You Need for Maximum Efficiency

-

The Best Pharmaceutical Coating Techniques for 2026

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity