Top 10 Tips for Choosing the Right Pharma Coating Machine for Your Needs

Choosing the right pharma coating machine is crucial for pharmaceutical manufacturers aiming to enhance the quality and efficiency of their products. With the rapid evolution of coating technologies, the market is flooded with various options designed to meet diverse production needs. However, selecting the most suitable pharma coating machine can be a daunting task, especially when considering factors like production capacity, coating uniformity, and compatibility with different formulations.

This guide aims to provide you with the top 10 tips for making an informed decision when choosing a pharma coating machine. By understanding the critical aspects of design, functionality, and operational efficiency, you can better align your equipment choice with your specific requirements. Whether you are a small-scale producer or part of a large pharmaceutical company, making the right investment in a coating machine can significantly impact your manufacturing process, leading to better product quality and increased market competitiveness.

Understanding Pharma Coating Processes and Their Importance

Pharmaceutical coating processes play a pivotal role in the development and manufacturing of various drug formulations. These processes enhance the stability, efficacy, and safety of medications while also improving patient compliance. Coatings can protect sensitive active pharmaceutical ingredients (APIs) from environmental factors such as moisture and light, thereby prolonging their shelf life. Additionally, coatings can mask unpleasant tastes or odors and facilitate the controlled release of the drug in the body, ensuring optimal therapeutic outcomes.

Understanding the different types of coating technologies available is crucial for selecting the right equipment. Some common coating methods include aqueous and solvent-based coatings, as well as polymeric and sugar-coated systems. Each technique offers distinct advantages depending on the specific formulation and desired release characteristics.

Furthermore, the choice of a coating machine should consider factors such as batch size, scalability, and ease of cleaning to ensure compliance with stringent regulatory standards in the pharmaceutical industry. By grasping the nuances of these processes, manufacturers can optimize their production capabilities while delivering high-quality pharmaceutical products that meet market demands.

Key Factors to Consider When Selecting a Coating Machine

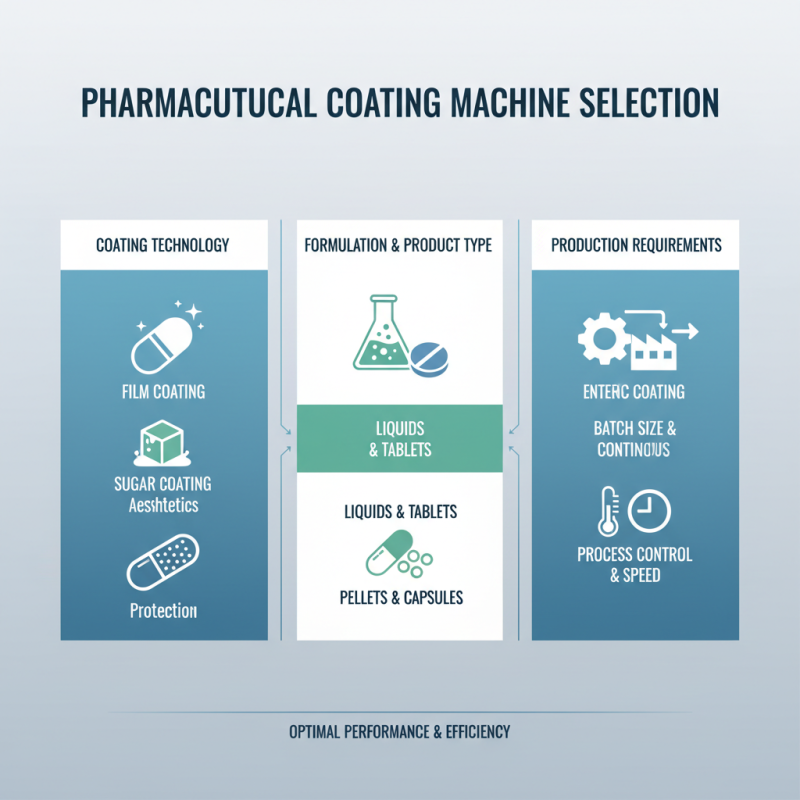

When selecting a coating machine for pharmaceutical applications, it's crucial to prioritize specific key factors to ensure optimal performance and efficiency. One important aspect is the type of coating technology employed. Depending on the formulation and production requirements, you may consider options like film coating, sugar coating, or enteric coating. Each technology comes with its own set of advantages and may be more suitable for different product types.

Additionally, the machine's capacity and scalability should align with your production goals. Evaluate the throughput and scalability options to accommodate future growth without requiring significant additional investments. Ease of cleaning and maintenance is another fundamental consideration, as it can directly influence production downtime and operational efficiency. Look for machines with user-friendly designs that facilitate rapid cleaning and changeover processes. By focusing on these critical factors, you can select a coating machine that not only meets your immediate needs but also supports long-term production objectives.

Types of Coating Machines Available in the Market

When selecting a pharma coating machine, it is essential to understand the various types available in the market to identify which best suits your specific production needs. The main categories of coating machines include fluid bed coaters, pan coaters, and high-shear granulators, each offering distinct advantages based on the application. Fluid bed coaters are particularly effective for uniform coating and are known for their efficient drying processes, making them ideal for producing layer-by-layer formulations. These machines utilize a fluidized bed to achieve even coating distribution, allowing for precise control over coating thickness.

On the other hand, pan coaters are favored for their versatility in manufacturing tablets and pellets, providing options for aqueous or non-aqueous coatings. These machines work by rotating the product in a circular pan while a spray system applies the coating solution, making them suitable for a range of applications from simple sugar coating to complex film coating. Additionally, high-shear granulators serve a dual purpose, effectively mixing and coating granules in a single cycle, which enhances production efficiency, particularly in the granulation of powders.

Understanding these types of coating machines and their specific functionalities can guide manufacturers in making informed decisions, ensuring that their production processes align with regulatory requirements and quality standards. Each machine offers unique benefits and considerations, further emphasizing the importance of a tailored approach when investing in pharmaceutical coating technology.

Assessing Your Production Scale and Output Requirements

When selecting a pharmaceutical coating machine, understanding your production scale and output requirements is paramount. A comprehensive analysis of your production needs will determine the type of equipment that will best fit your operation. According to a report published by the International Society for Pharmaceutical Engineering, manufacturers often experience a 20% increase in efficiency when their equipment aligns perfectly with their production volume. Thus, before making any purchasing decisions, evaluate how many batches you plan to produce per hour and the size of each batch.

Tip: Consider scalability. If your production demands fluctuate, opt for a coating machine with modular designs that can be easily upgraded or expanded. This flexibility ensures that you are not locked into a single capacity and can adapt to changing market demands without significant reinvestment.

Moreover, evaluating your output quality requirements is equally crucial. According to a survey by GlobalData, 45% of pharmaceutical companies reported that inconsistent coating quality led to increased rejection rates and product recalls. It’s essential to choose a machine that not only meets your current output demands but is also capable of delivering high-quality coatings consistently.

Tip: Research precision and control features of the coating machines. Advanced models often come equipped with automated control systems that allow for real-time adjustments during the coating process, thereby ensuring that batch quality is maintained. This capability can save time and resources, contributing significantly to your bottom line.

Evaluating Maintenance and Support Services for Coating Equipment

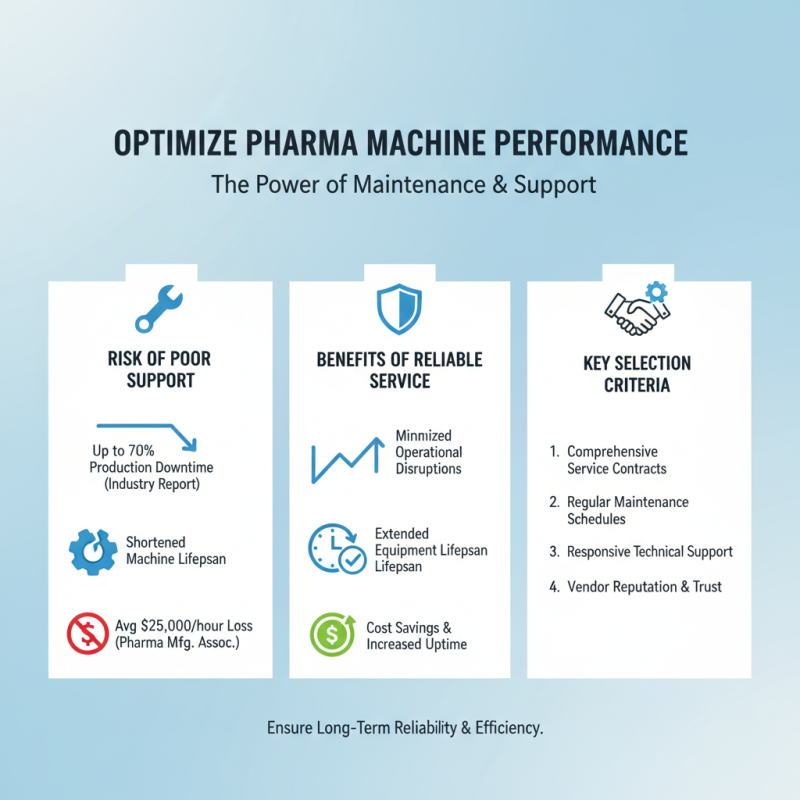

When selecting a pharmaceutical coating machine, considering the maintenance and support services is crucial to ensure long-term performance and reliability. A recent industry report highlights that up to 70% of companies experience production downtime due to inadequate maintenance and support services related to their coating equipment. Having a reliable support system in place not only minimizes operational disruptions but also extends the lifespan of the machinery. Prioritizing vendors that offer comprehensive service contracts with regular maintenance schedules can prevent unexpected failures, which, according to data from the Pharmaceutical Manufacturing Association, can cost firms significant losses, averaging around $25,000 per hour of downtime.

Furthermore, understanding the type of support services available can greatly influence the overall efficiency of your operations. Many pharmaceutical companies today prefer equipment providers that offer remote support capabilities, allowing for quick troubleshooting and reduced waiting times for repairs. Reports suggest that organizations utilizing such services can improve their operational efficiency by approximately 30%. It's also essential to evaluate the training and onboarding programs provided by the manufacturer, as these can significantly impact the machine's operational efficiency. Investing in proper training ensures that your team can maximize the equipment's potential while adhering to the industry's stringent standards for quality and compliance. Ultimately, making informed decisions about maintenance and support services can lead to enhanced productivity and reduced total cost of ownership for pharmaceutical coating machines.

Related Posts

-

How to Choose the Best Film Coating for Your Projects and Applications

-

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process