Top 10 Essential Tablet Coating Machine Parts You Need to Know

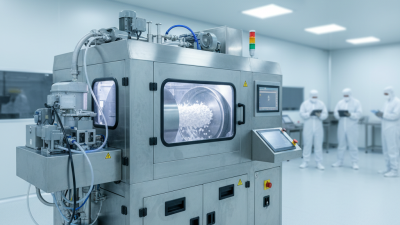

In the realm of pharmaceutical manufacturing, tablet coating is a crucial process that enhances the stability, appearance, and effectiveness of tablets. Understanding the intricacies of tablet coating machinery is essential for optimizing production efficiency and ensuring product quality. One of the key aspects of this machinery is the various tablet coating machine parts that contribute to its overall performance.

This article delves into the top 10 essential tablet coating machine parts you need to know. Each component plays a vital role in the operational success of the machine, from the spray guns that evenly distribute the coating solution to the curing systems that ensure proper drying. Familiarity with these parts not only helps in maintaining the equipment but also aids in troubleshooting and upgrading processes. By examining these essential components, manufacturers can make informed decisions that lead to enhanced output and improved product consistency, ultimately supporting the rigorous demands of the pharmaceutical industry.

Essential Components of a Tablet Coating Machine

Tablet coating machines are essential in the pharmaceutical industry, ensuring that tablets not only have the required efficacy but also possess improved appearance, stability, and taste. Understanding these machines' core components can significantly enhance their efficiency and output quality. The primary elements include the coating pan, which serves as the core of the process where tablets are placed for coating. This component is designed to provide optimal rotation and airflow to facilitate even coating application.

Another vital part is the spray nozzle, which is responsible for atomizing the coating solution so that it can be evenly distributed over the tablets. This component's precision directly affects the thickness and uniformity of the coating. Additionally, the control panel plays a crucial role, allowing operators to monitor and adjust parameters such as temperature, airflow, and coating solution flow rate, ensuring that the process runs smoothly and effectively.

Understanding these essential components enables manufacturers to optimize their tablet coating processes, leading to better product quality and increased production efficiency.

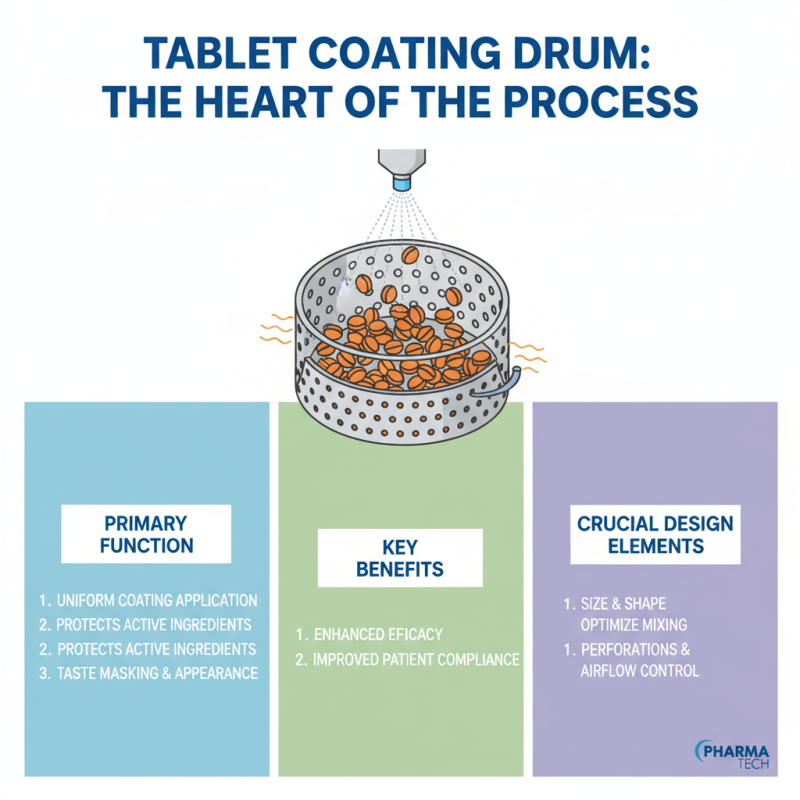

Understanding the Role of the Coating Drum in Production

The coating drum is a pivotal component in tablet coating machines, serving as the heart of the coating process. Its primary function is to provide a controlled environment where tablets are evenly coated with a film or sugar solution, which enhances their appearance, protects the active ingredients, and improves patient compliance through taste masking. The design of the coating drum, including its size and shape, is crucial, as it dictates how efficiently the tablets are mixed and how effectively the coating is applied.

Moreover, the rotation speed of the coating drum plays a significant role in determining the quality of the coating. A well-calibrated rotation speed ensures that the tablets tumble smoothly, promoting an even distribution of the coating solution. This is essential to avoid issues such as uneven coating or excessive buildup in certain areas, which can compromise the final product. Additionally, the drum's internal configuration often features baffles, which help to enhance mixing by directing the flow of tablets and coating materials, thereby maximizing the efficiency of the coating process. Understanding these aspects of the coating drum can lead to better production practices and improved tablet quality in pharmaceutical manufacturing.

Importance of Spray Nozzles for Even Coating Distribution

In the realm of pharmaceutical manufacturing, ensuring an even and consistent coating on tablets is critical for both aesthetic and functional purposes. One of the key components in achieving this is the spray nozzle used in tablet coating machines. According to a report by Pharmaceutical Technology, nearly 60% of production downtime in coating processes can be attributed to uneven spray patterns, which underline the importance of choosing high-quality nozzles. Properly designed spray nozzles provide a uniform distribution of the coating solution, which helps in preventing issues such as overcoating or undercoating, ultimately influencing the dissolution profile of the tablets.

Additionally, the design and positioning of spray nozzles can significantly impact the efficiency of the coating process. A recent analysis published in the International Journal of Pharmaceutics highlights that optimizing the spray angle and droplet size can enhance the deposition rate by up to 40%. This not only ensures better coating uniformity but also reduces the amount of coating material wasted during production. As manufacturers continue to seek improvements in their coating processes, investing in advanced spray nozzle technology becomes essential for maintaining product quality and operational efficiency.

The Functionality of the Air Handling System in Coating Machines

The air handling system in tablet coating machines plays a critical role in ensuring an optimal coating process. This system is responsible for regulating airflow, temperature, and humidity within the coating chamber, which directly impacts the quality and uniformity of the coating. By maintaining the ideal environmental conditions, the air handling system ensures that the coating material is evenly distributed across the tablet surfaces, facilitating a smooth and consistent layer formation.

Furthermore, the air handling system aids in the drying process of the coated tablets. It helps remove excess moisture by circulating heated air throughout the chamber. This drying stage is crucial to prevent issues such as clumping or inadequate adhesion of the coating material. Additionally, the efficient management of airflow minimizes the risk of contamination, as it helps keep the coating environment clean and controlled. Overall, a well-designed air handling system is essential for maximizing the efficiency and effectiveness of tablet coating operations.

Essential Parts of Tablet Coating Machines

Key Features of Control Systems for Optimal Operations

When it comes to tablet coating machines, the control system is a vital component that determines the efficiency and effectiveness of the coating process. Key features of these control systems typically include touch-screen interfaces for user-friendly operation, programmable logic controllers to manage complex processes, and real-time monitoring capabilities to ensure consistent quality. A robust control system can significantly reduce downtime and enhance productivity by allowing for quick adjustments and detailed reporting on operational performance.

Tips: When evaluating control systems for tablet coating machines, consider the ease of integration with existing equipment. An intuitive interface can greatly expedite operator training and streamline workflow. Additionally, ensure that the system offers diagnostic tools that alert operators to potential issues before they escalate, which can save valuable time and resources.

Another crucial aspect to consider is the ability to customize settings for different coating formulations and production requirements. Advanced control systems allow for precise parameter adjustments, such as temperature, humidity, and spray rates, which are essential for achieving the desired coating quality. This level of control not only improves consistency across batches but also enhances the final product’s appearance and performance.

Tips: Regularly update the control system software to leverage advancements in technology, which can provide enhanced functionalities and improved performance metrics. Keeping abreast of system updates can help maintain the competitiveness and efficiency of your production line.

Top 10 Essential Tablet Coating Machine Parts You Need to Know - Key Features of Control Systems for Optimal Operations

| Part Name | Description | Key Features | Importance |

|---|---|---|---|

| Control Panel | Interface for operators to control machine settings. | User-friendly design, touchscreen interface, real-time monitoring. | Crucial for effective machine operation and ease of use. |

| Coating Pan | Container where tablets are coated with a film. | Uniform coating, adjustable speed, easy cleaning. | Essential for achieving consistent tablet quality. |

| Air Handling Unit | Regulates air flow and temperature inside the coating pan. | Temperature control, humidity regulation, efficient filtration. | Critical for preventing moisture-related issues in coating. |

| Spray System | Applies the coating solution onto the tablets. | Precision nozzle design, adjustable spray pattern, automated control. | Ensures even and effective application of coating materials. |

| Drying System | Removes moisture from coated tablets. | Optimized air flow, adjustable drying time, energy efficiency. | Prevents defects related to moisture in coatings. |

| Sensors | Monitor various parameters during the coating process. | Temperature sensors, humidity sensors, speed sensors. | Vital for maintaining optimal operating conditions. |

| Vibration System | Ensures even distribution of tablets within the pan. | Adjustable frequency and amplitude for optimal performance. | Enhances coating uniformity and prevents clumping. |

| Software Control | Software systems that control and monitor the coating process. | Data logging, recipe management, remote access capabilities. | Facilitates optimization and standardization of processes. |

| Mechanical Structure | Physical components that support the machinery. | Sturdy design, vibration dampening, ease of maintenance. | Important for durability and reliability of the machine. |

| Control Logic Board | Central processing unit for machine operations. | Real-time processing, fault detection, control of various components. | Essential for overall functionality and safety of the equipment. |

Related Posts

-

Top Benefits of Using Continuous Coating Machines in Manufacturing Process

-

What is Pharmaceutical Coating and How Does It Impact Drug Delivery

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity

-

Top 10 Tips for Choosing the Right Pharma Coating Machine for Your Needs