What is a Perforated Pan System and How Does It Work?

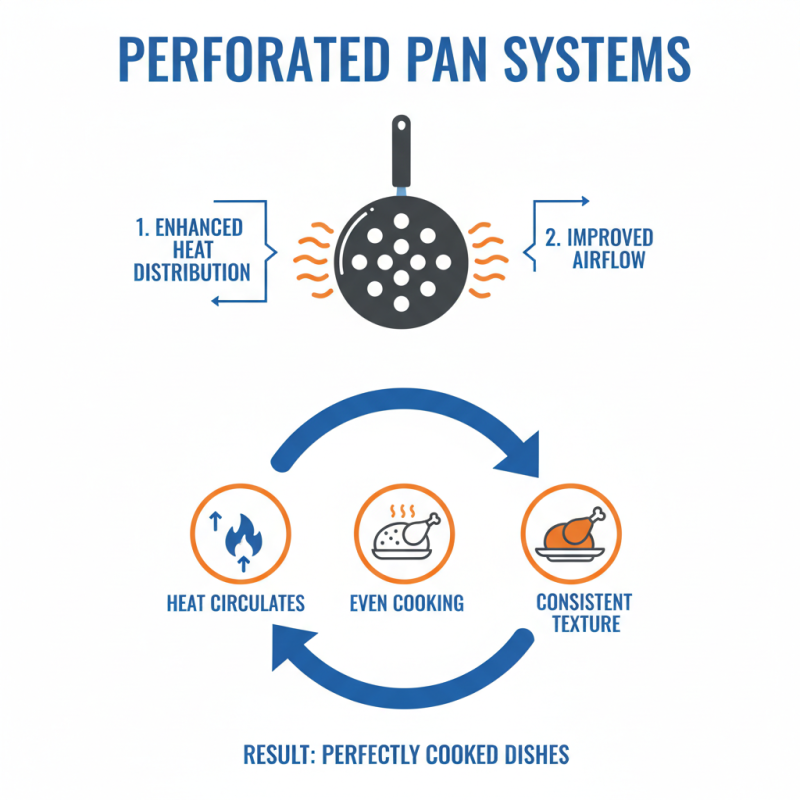

The perforated pan system is an innovative cooking method. It uses a pan with holes to enhance food preparation. This approach allows heat and moisture to circulate freely around the food. As a result, it leads to even cooking and improved textures.

Many chefs appreciate the benefits of a perforated pan system. It is particularly useful for roasting vegetables and baking pizza. These applications highlight its versatility in the kitchen. The unique design aids in achieving crispy exteriors while keeping the insides tender. This dual benefit can transform ordinary meals into restaurant-quality dishes.

However, not all users are aware of its potential limitations. Some may find the cleaning process tedious. Others might struggle with maintaining an even cooking temperature. Yet, these challenges can lead to valuable learning experiences. Ultimately, understanding how a perforated pan system works can elevate culinary skills and inspire creativity in the kitchen.

Overview of Perforated Pan Systems and Their Applications

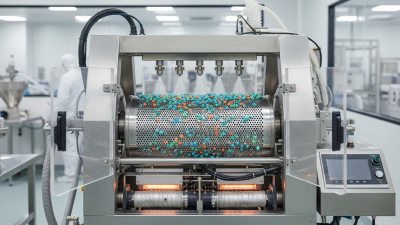

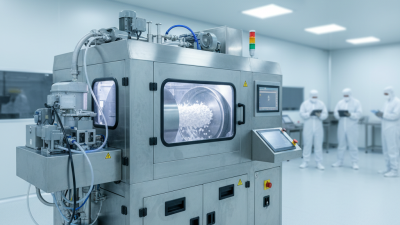

Perforated pan systems are widely used in various industries, particularly in food processing and chemical manufacturing. These systems allow for efficient drainage, air circulation, and heat distribution. According to a market report from Smithers Pira, the food processing sector is expected to see significant growth, with perforated pans playing a crucial role in enhancing product quality.

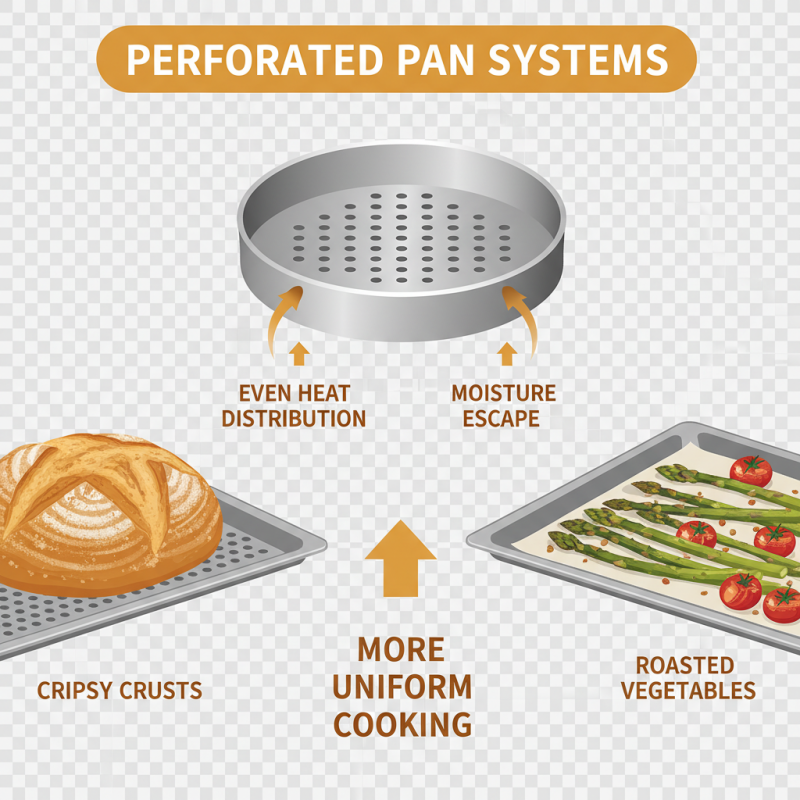

The design of a perforated pan features numerous holes or slots, which improve airflow. In baking, they promote even cooking and help achieve a golden crust. However, flaws can arise if the hole sizes are not optimized. For different products, manufacturers should consider the ideal diameter to avoid excess moisture retention. A study conducted by the Institute of Food Technologists found that the correct perforation can enhance baking efficiency by 25%.

In chemical applications, these perforated systems help maintain consistent reaction conditions. For instance, when mixing ingredients, proper dispersion of gases is vital. The percentage of allowable deviation in airflow can significantly affect the output quality. Companies must often refine their processes to minimize such variances, which can lead to unpredictable results. Regular audits are essential, yet many firms overlook this crucial aspect.

Applications of Perforated Pan Systems

Key Components of a Perforated Pan System

A perforated pan system is essential in various industrial processes. At its core, the system includes several key components that ensure effective operation. The primary component is the pan itself, designed with numerous small holes. These holes allow for the efficient drainage of liquids and gases. Typically, these pans are made of durable materials to withstand harsh conditions.

Another critical element is the support frame. This frame holds the pan securely in place. A well-structured frame can prevent vibrations that might affect processes. Additionally, various types of filters can be integrated. Filters further enhance the system by capturing particulates, improving overall performance. According to industry reports, incorporating advanced filtration can lead to a 20% increase in efficiency.

Moreover, monitoring sensors have become increasingly important. These sensors track fluid levels, flow rates, and pressure. Data collected can lead to better decision-making and process adjustments. However, challenges remain. Systems can face clogging issues, which may cause downtime. Regular maintenance is crucial to address these problems. Companies often underestimate the need for routine checks. Awareness of system limitations is necessary for optimal functioning.

| Component | Description | Function | Common Materials |

|---|---|---|---|

| Perforated Pan | A pan with holes designed to allow airflow and drainage | Facilitates even cooking and better heat distribution | Aluminum, Steel |

| Heating Element | Device that generates heat for cooking | Heats up the pan for cooking food | Electric coils, Gas burner |

| Temperature Controller | Regulates the heat within the system | Ensures optimal cooking temperature | Digital sensors, Thermostats |

| Ventilation System | System that circulates air around the pan | Enhances cooking efficiency and prevents hot spots | Fans, Ducts |

| Support Structure | Framework that holds the pan and components | Provides stability and weight distribution | Stainless steel, Aluminum |

How Perforated Pan Systems Facilitate Heat Distribution

Perforated pan systems are designed to enhance heat distribution in cooking. These pans feature multiple small holes that allow for better airflow. As heat circulates, it reaches food more evenly. This results in well-cooked dishes with consistent texture.

Using a perforated pan can also create a unique cooking experience. It allows excess moisture to escape. For items like vegetables, this promotes a crisp texture. However, some cooks may find it tricky at first. Proper placement in the oven matters. If too close to a heat source, food can burn quickly.

Tips: Start with lower temperatures and monitor cooking times. Adjust as needed for different recipes. Experimentation can lead to great results. Remember, patience is key. Not every dish will turn out perfectly on the first try.

Benefits of Using Perforated Pan Systems in Cooking

Perforated pan systems have gained popularity in cooking for their unique advantages. These pans feature small holes that allow for even heat distribution and moisture escape. When using a perforated pan, food cooks more evenly. Crispy crusts on bread and roasted vegetables benefit greatly.

Using a perforated pan can enhance flavors in various dishes. The holes allow hot air to circulate, which improves browning. For instance, when baking, this method can help achieve a crunchy exterior without overcooking the inside. Some people may struggle with timing, though. Baking too long can lead to dry outcomes.

Tips for using a perforated pan include preheating the pan. This helps to jump-start the cooking process. Also, avoid overcrowding the pan. Leaving space for airflow is key. Something to consider is the food sticking to the pan. Using a light coat of oil or parchment paper can help with that issue. These strategies can make cooking less frustrating and more enjoyable.

Maintenance and Care for Perforated Pan Systems

Maintaining a perforated pan system is crucial for optimal performance. Regularly inspect the pan for any build-up or blockages. Even small debris can impact drainage and efficiency. It's essential to clean the perforations weekly. Use a brush or compressed air to remove particles stuck in the holes. This step often gets overlooked but can significantly enhance the system's lifespan.

Water quality also plays a role in maintenance. Hard water can leave mineral deposits in the system. If you notice scaling, consider using vinegar or a specialized descaling solution. Rinsing the system thoroughly afterwards is essential. Neglecting this could lead to long-term damage.

Check the seals and gaskets regularly as well. Wear and tear can create leaks. A small leak might not seem serious, but it can escalate. Identifying these issues early can save you time and money. Keep a maintenance log to track any recurring problems. This will help you spot patterns and areas needing more attention.

Perforated pan systems require diligence, but the rewards of a well-maintained system are significant.

Related Posts

-

Top 10 Essential Tablet Coating Machine Parts You Need to Know

-

Top 10 Tips for Choosing the Right Pharma Coating Machine for Your Needs

-

How to Choose the Best Pharmaceutical Coating Machine for Your Needs

-

How to Choose the Best Perforated Pan Coating Machine for Your Business

-

How to Choose the Best Film Coating for Your Projects and Applications

-

How to Optimize Tablet Manufacturing for Increased Efficiency and Quality