Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

The pharmaceutical industry constantly seeks ways to enhance production efficiency while maintaining high-quality standards. One of the critical processes in pharmaceutical manufacturing is the coating of tablets, which serves not only to protect active ingredients but also to improve the overall consumer experience. The advancements in tablet coating systems have led to significant improvements in the efficiency and effectiveness of production lines.

This article explores the top 10 tablet coating systems that have been recognized for their innovative technology and contributions to the pharmaceutical sector. These systems are designed to streamline operations, reduce production times, and enhance coating uniformity, which ultimately contributes to better therapeutic outcomes. By incorporating the latest advancements in tablet coating systems, manufacturers can achieve superior quality control and operational efficiency, providing a solid foundation for a competitive edge in the market.

As the demand for pharmaceutical products continues to rise, embracing state-of-the-art tablet coating systems becomes increasingly vital. By evaluating these leading systems, manufacturers can identify solutions that will not only optimize their production processes but also respond effectively to regulatory standards and consumer expectations.

Overview of Tablet Coating Systems in Pharmaceutical Production

In the realm of pharmaceutical production, tablet coating systems play a critical role in enhancing both the efficacy and efficiency of drug manufacture. The application of these systems not only improves the aesthetic appeal of tablets but also functions as a barrier against moisture, oxygen, and light, preserving the stability and integrity of active pharmaceutical ingredients (APIs). According to the "Pharmaceutical Manufacturing Market Trends 2023" report, effective coating can increase tablet bioavailability by up to 30%, thereby facilitating patient compliance and therapeutic effectiveness.

When selecting a tablet coating system, it is essential to consider factors such as coating uniformity, drying efficiency, and compatibility with various formulations. Innovations such as fluidized bed technologies have revolutionized the process, enabling uniform coating without excessive heat application, thereby protecting sensitive compounds. Furthermore, recent studies highlight the potential for continuous manufacturing processes to streamline operations and improve throughput, thus meeting increasing market demands without compromising quality.

**Tip:** To maximize productivity, conduct thorough evaluations of your equipment's scalability. Identify systems that can be adjusted or upgraded as production needs evolve, thereby avoiding costly investments in new machinery in the future.

**Tip:** Regular maintenance and calibration of coating systems are essential. Utilizing predictive maintenance strategies can minimize downtime and ensure that machinery operates at optimal efficiency, contributing to a smoother production process.

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

Importance of Coating in Enhancing Drug Bioavailability

The importance of coating in enhancing drug bioavailability cannot be overstated, particularly in the realm of pharmaceutical production. Coating systems not only protect the active pharmaceutical ingredients (APIs) from environmental factors like moisture and light but also play a crucial role in controlling the release profile of the drug. According to a report by Grand View Research, the global pharmaceutical coating systems market is expected to reach approximately $9.62 billion by 2025, demonstrating a robust growth driven by advancements in coating technologies and increased demand for improved drug formulations.

Moreover, the application of coatings can significantly enhance the solubility of poorly water-soluble drugs. A study published in the Journal of Controlled Release indicates that up to 40% of new chemical entities are poorly soluble, which directly impacts their bioavailability. By employing specialized coatings, pharmaceutical manufacturers can improve the dissolution rates of these compounds, thereby enhancing their absorption in the gastrointestinal tract. This is particularly pertinent given that the oral route remains the most preferred method for drug delivery, where achieving optimal bioavailability is vital for therapeutic efficacy.

In light of these factors, the selection of the right tablet coating system becomes critical, as it can lead to improved production efficiency and higher product quality. Advancements in technologies such as spray coating and film coating not only streamline the production process but also facilitate compliance with regulatory standards aimed at ensuring patient safety and drug efficacy. As the industry continues to innovate, the potential for enhanced bioavailability through effective coating strategies will undoubtedly remain a focal point in pharmaceutical development.

Criteria for Selecting Effective Tablet Coating Systems

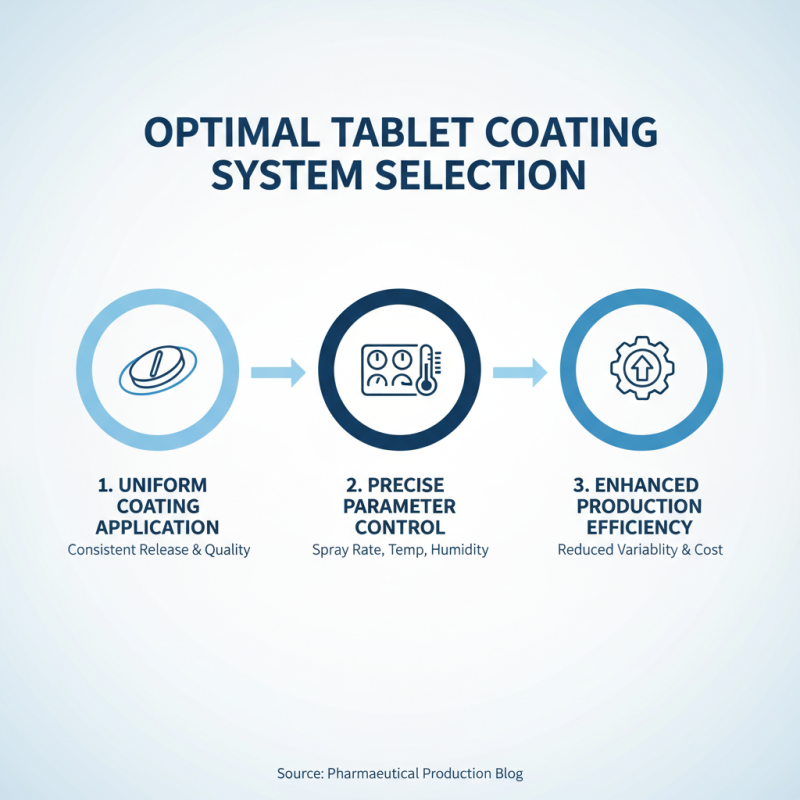

When selecting an effective tablet coating system, several critical criteria must be considered to enhance pharmaceutical production efficiency. First and foremost, the coating system should offer uniformity in coating application. This attribute not only ensures consistent release profiles but also minimizes variability between batches, which is essential for maintaining product quality. Furthermore, the ability to achieve precise control over the coating parameters, such as spray rate, temperature, and humidity, directly impacts the efficiency and quality of the production process.

Another vital factor is the ease of integration with existing manufacturing processes. An ideal tablet coating system should be compatible with various production lines and equipment to facilitate a seamless workflow. This includes consideration of setup times, maintenance requirements, and the flexibility to coat different tablet sizes and formulations. Lastly, the system should prioritize environmental sustainability by employing techniques that reduce solvent use and waste, subsequently lessening the overall carbon footprint while adhering to regulatory compliance. Ultimately, these criteria together contribute to a more efficient, reliable, and environmentally responsible tablet production operation.

Top Features of Leading Tablet Coating Technologies

The efficiency of pharmaceutical production can significantly benefit from advancements in tablet coating technologies. Leading systems today prioritize precision and uniformity in coating processes, ensuring that each tablet is encased in a consistent layer. This uniformity not only enhances the aesthetic appeal of the final product but also impacts the drug's release properties, bioavailability, and overall effectiveness. A state-of-the-art tablet coating system often integrates advanced spray technologies that deliver fine droplets, allowing for even distribution across tablet surfaces, which is critical for maintaining quality standards.

Furthermore, modern tablet coating systems incorporate real-time monitoring and automated controls to optimize production efficiency. These features enable manufacturers to adjust parameters instantaneously, reducing downtime and minimizing waste. Enhanced drying technologies increase throughput by ensuring tablets are adequately dried to prevent moisture-related issues, which can compromise stability and shelf life. Additionally, many systems now support continuous production processes, which streamline operations and reduce labor costs, ultimately enhancing productivity in pharmaceutical manufacturing. These top features come together to drive significant improvements in efficiency and product quality in the pharmaceutical industry.

Future Trends in Tablet Coating for Pharmaceutical Efficiency

The landscape of tablet coating technology is rapidly evolving, driven by the pharmaceutical industry's urgent need for enhanced production efficiency and product quality. Future trends indicate a strong shift towards more automated and intelligent systems, which utilize advanced data analytics and real-time monitoring. These innovations promise to streamline manufacturing processes, reduce human error, and ensure consistent coating properties, ultimately leading to shorter production cycles and lower operational costs.

Moreover, sustainable practices are becoming a focal point within tablet coating systems. The industry is exploring eco-friendly coating materials and processes that minimize waste and energy consumption. The integration of green chemistry principles in the development of coating formulations allows for the reduction of solvents and hazardous substances, aligning with global sustainability goals. As pharmaceutical companies strive to meet regulatory compliance and consumer expectations for environmentally responsible practices, these advancements in tablet coating will play a crucial role in shaping the future of pharmaceutical production efficiency.

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

| Coating System | Coating Type | Efficiency Improvement (%) | Features | Future Trends |

|---|---|---|---|---|

| Automatic Coater 1 | Film Coating | 15% | High precision, Temp control | Smart technology integration |

| Automatic Coater 2 | Sugar Coating | 10% | Enhanced finish, Faster operation | Eco-friendly materials |

| Pilot Coater | Micro-coating | 20% | Flexibility, Scale-up potential | Personalized medicine applications |

| Batch Coater | Film Coating | 18% | Uniform coating, Easy cleaning | Automation and data analytics |

| Continuous Coater | Film Coating | 25% | Consistent quality, Reduced time | Real-time monitoring |

| Laboratory Coater | Top-spray Coating | 12% | Small scale, Quick adjustments | Rapid prototyping |

| Super Coater | Film Coating | 22% | High throughput, Versatility | Hybrid technology |

| Mini Coater | Glazing | 8% | Compact size, Easy transport | Increased adaptability |

| Advanced Coater | Spray Coating | 15% | Heat control, Fast setup | Smart development tools |

| Smart Coater | Functional Coating | 30% | Integration with AI, Customizable | AI-assisted optimization |