Top 10 Tablet Coating Machine Parts You Need for Maximum Efficiency

In the ever-evolving landscape of pharmaceutical manufacturing, the role of tablet coating machines has never been more critical. According to Dr. Emily Thompson, a leading expert in pharmaceutical engineering, "The efficiency of tablet production is heavily reliant on the precision and quality of individual tablet coating machine parts." This statement underscores the importance of understanding and optimizing the components that make up these machines to enhance their performance.

As manufacturers strive for maximum efficiency in their processes, identifying the top tablet coating machine parts becomes essential. Each component plays a pivotal role, from ensuring even coating application to maintaining the integrity of the tablets during production. In this article, we will explore the ten key parts that can significantly improve the performance and reliability of tablet coating operations, thus leading to better product quality and reduced downtime.

By focusing on these crucial elements, industry professionals can not only increase productivity but also ensure adherence to the highest standards of quality control. As we delve deeper into the anatomy of tablet coating machines, it becomes evident that investing in the right tablet coating machine parts is not just a necessity but a strategic move towards achieving operational excellence.

Top 10 Essential Parts for Tablet Coating Efficiency

When it comes to tablet coating processes, ensuring maximum efficiency is primarily linked to the crucial parts that make up the coating machine. One of the most essential components is the coating pan. The design and material of the pan can significantly impact the uniformity and quality of the coating. A high-quality pan promotes even distribution of coating materials and facilitates optimal airflow, which are vital for achieving consistent results.

Another indispensable part is the spray nozzle. The nozzle's specifications, including the size and shape, play a critical role in the application of the coating solution. Fine, uniform spray patterns help to minimize wastage and enhance adhesion to the tablet surface. Additionally, temperature control units are key to maintaining the right conditions during the coating process. Consistent temperature ensures that the coating solution performs as intended, preventing issues like clumping or improper drying.

Together, these essential parts not only contribute to the efficiency of the tablet coating process but also improve the overall quality of the final product.

Understanding Different Types of Tablet Coating Machines and Their Components

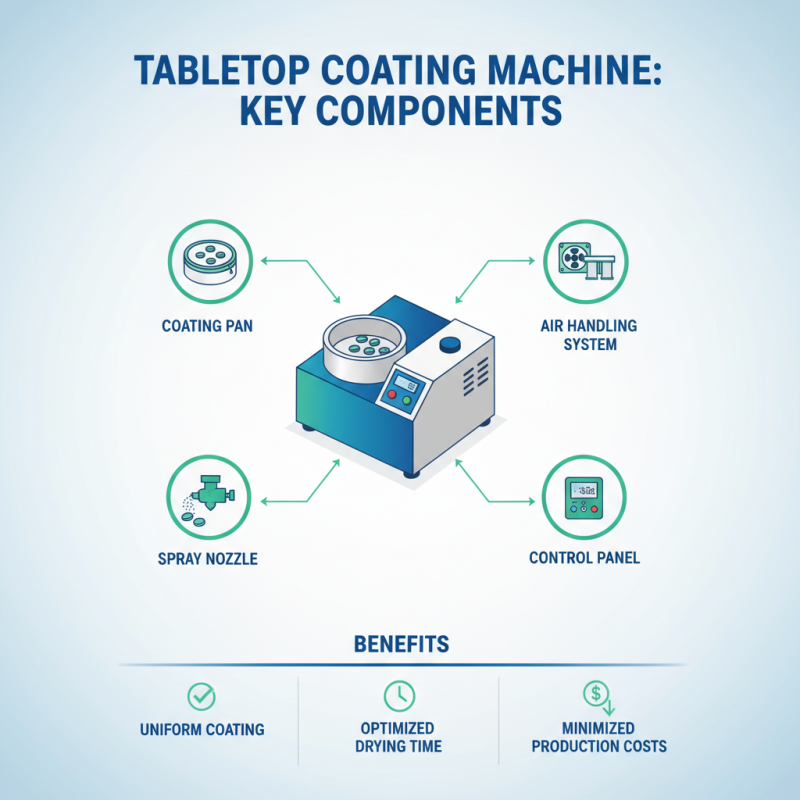

Tablet coating machines are essential in the pharmaceutical and nutraceutical industries, playing a crucial role in the production of coated tablets. Understanding the various components of these machines can significantly enhance their operational efficiency. Key elements include the coating pan, air handling system, spray nozzle, and control panel. Each component contributes to achieving a uniform coating while optimizing drying time and minimizing production costs.

Recent industry reports indicate that the efficiency of tablet coating processes can increase by up to 30% when equipped with advanced spray nozzles and precise air handling systems. For instance, modern tablet coating machines are adopting high-efficiency nozzles that ensure uniform distribution of coating material, essential for obtaining the desired finish and protecting the tablet's integrity. Furthermore, innovations in process control technology allow for real-time adjustments, ensuring consistency throughout production.

Additionally, the choice of coating material and the design of the coating pan play critical roles in defining the coating process efficiency. Data from the pharmaceutical manufacturing sector suggests that integrating robust materials in the construction of coating pans can enhance durability, leading to longer operational life and reduced maintenance costs. By investing in the right components and optimizing machine configurations, manufacturers can achieve significant improvements in both productivity and product quality.

Key Performance Indicators for Coating Machine Parts in Pharma Industry

In the pharmaceutical industry, the efficiency of tablet coating machines significantly impacts production scale and product quality. The Key Performance Indicators (KPIs) for these machines revolve around factors such as batch uniformity, coating thickness consistency, and processing time. According to the Pharmaceutical Manufacturing Industry Report, a 20% increase in coating uniformity can lead to a 15% reduction in rework, showcasing the importance of precise component performance in enhancing operational efficiency.

One critical part is the atomization nozzle, which directly affects the distribution and the thickness of the coating. A recent study indicated that optimizing the nozzle design can lead to a 30% improvement in coating uniformity. Regular maintenance and timely replacement of worn nozzles ensure that the coating process runs smoothly, ultimately improving the final product’s quality.

Tip: Consider investing in advanced monitoring systems to keep track of the KPIs in real-time. These systems can provide insights into operational efficiency and alert operators to any deviations from the desired performance standards. Furthermore, data analytics could enhance predictive maintenance, allowing for proactive management of machine parts and reducing the likelihood of downtime.

Impact of Quality Parts on Coating Uniformity and Product Consistency

The quality of components utilized in tablet coating machines plays a crucial role in achieving coating uniformity and ensuring product consistency. High-quality parts, such as precision spray nozzles and reliable control systems, are essential for delivering a consistent coating thickness across the tablets. Variations in spray patterns or flow rates can lead to uneven coating, which not only affects the aesthetic appeal of the product but also impacts its performance and stability. Therefore, investing in superior parts contributes significantly to maintaining high standards in manufacturing processes.

Moreover, regular maintenance and the use of durable materials in machine components minimize downtime and enhance operational efficiency. Components like robust agitators and efficient drying systems help maintain an optimal coating environment, reducing the likelihood of defects. This efficiency translates to better product consistency, ensuring that each batch meets the desired quality specifications. In essence, the careful selection and maintenance of tablet coating machine parts directly influence the overall productivity and reliability of the coating process, underscoring the importance of quality in manufacturing capabilities.

Top 10 Tablet Coating Machine Parts Impacting Efficiency

This bar chart illustrates the impact of various tablet coating machine parts on overall efficiency, rated from 1 to 10. Understanding the contribution of each component can highlight areas for improvement in coating uniformity and product consistency.

Maintenance Strategies to Enhance the Lifespan of Coating Machine Parts

To ensure the longevity and efficiency of tablet coating machines, maintenance strategies play a crucial role in optimizing the performance of key components. Regular inspections and timely replacements of critical parts can significantly reduce downtime and production costs. According to a market analysis report by Grand View Research, nearly 30% of operational inefficiencies in pharmaceutical manufacturing can be attributed to equipment malfunction due to inadequate maintenance. Therefore, implementing a robust maintenance schedule is essential for maximizing the lifespan of coating machine parts.

One effective maintenance strategy is the adoption of predictive maintenance technologies, which use data analytics to foresee equipment failures before they occur. This approach can reduce maintenance costs by up to 25% and improve machine reliability, as noted in a study published by the Journal of Pharmaceutical Sciences. Additionally, maintaining optimal environmental conditions, such as controlling humidity and temperature in coating areas, has been shown to enhance machine performance and prolong the life of components. By prioritizing these maintenance strategies, pharmaceutical companies can not only ensure consistent product quality but also achieve significant cost savings in the long run.

Related Posts

-

Why Coating Pan Tablets are Essential for Efficient Tablet Production

-

Top 10 Essential Tablet Coating Machine Parts You Need to Know

-

How to Choose the Best Film Coating for Your Projects and Applications

-

Top 10 Benefits of Using a Tablet Coating Pan for Efficient Coating Process

-

Top 10 Tablet Coating Systems for Improved Pharmaceutical Production Efficiency

-

How to Choose the Best Tablet Coating for Optimal Protection and Longevity